Electric mobility is becoming increasingly important in the automotive industry. The number of electrically powered vehicles produced is increasing. MAPAL already offers a wide range of innovative machining solutions for the manufacture of individual parts and components that are machined.

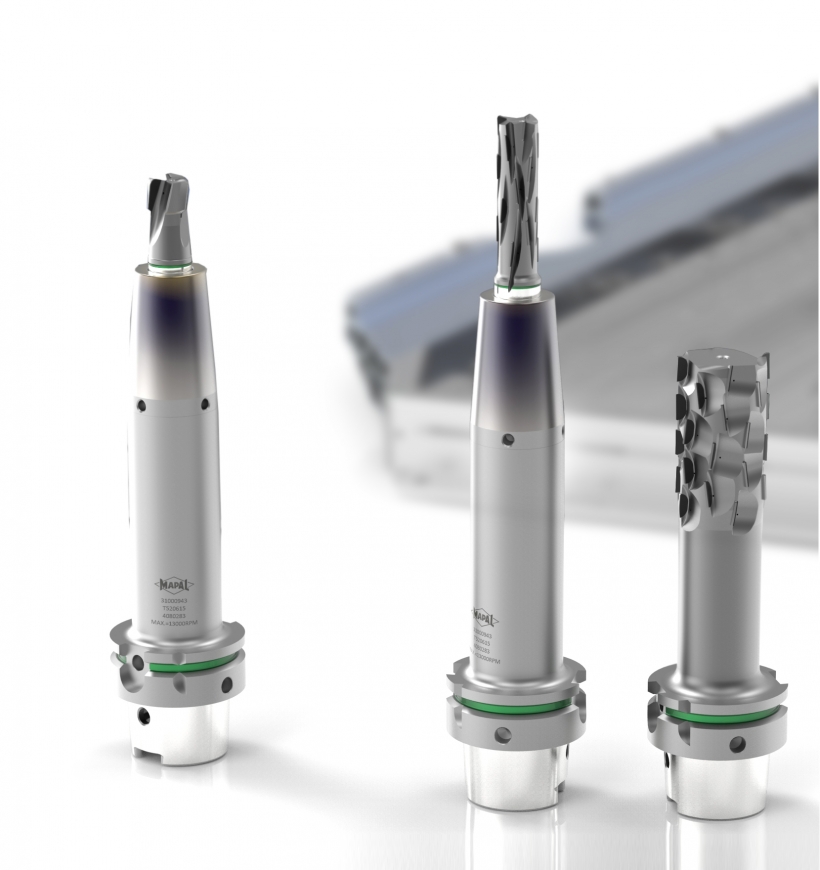

MAPAL has developed a fine boring tool in ultralight design for machining the main bore in stator housings.

High precision for large diameters using ultralight tools

The high-precision machining of the main bore in stator housing presents a challenge for tool and machine. All other steps in the production of the stator housing could be carried out on machines with HSK A63 spindle. For the main bore, however, a machine with HSK A100 spindle had to be used. That is due on the one hand to the high cutting torques of up to 500 Nm, and on the other hand to the maximum permissible tool weight and tilting moment. Cost-effective manufacturing with short cycle times calls for a solution in which the complete machining can be carried out on one machine with small connections, as these machines are characterised by their high spindle speeds, lower investment and operating costs and lower energy consumption. To meet these demands, MAPAL has developed a fine boring tool of ultralight design. The low weight of around 10 kg meets the precondition for use on machines with smaller spindles. In addition to the weight, MAPAL has also optimised the cooling channels, a special back-flushing system ensures a far more effective removal of the chips, thus preventing chips from scratching the machined surface.

For the chatter-free machining of the different variants of the battery housing MAPAL offers the necessary tools with the optimal strategy.

Chatter-free machining of highly complex thin-walled battery housings

MAPAL offers the necessary tools with the optimal strategy for the different variants of the battery housing. PCD as cutting material and the MQL technology are used for maximum cost-effectiveness. Different milling technologies are employed to reduce the cutting forces, depending on the required stock removal, machining application and component. For certain contours, for example, the use of milling cutter for high-volume machining can be expedient. The SPM milling cutter from MAPAL is suited to this application. Thanks to its high positive cutting edge geometry and the optimised chip flutes, the cutting force is reduced by up to 15 percent compared with conventional milling cutters. If, for example, deep pockets are to be machined, MAPAL employs special PCD milling cutters whose cutting edges are arranged with both positive and negative axis angle. In combination with the trochoidal milling strategy, the cutting force is kept very low even in this machining operation – despite the material-removal rate over the entire depth of the pocket.

With the tools from MAPAL the close shape and position tolerances can be reliably achieved.

Spiral forms with tolerances in the µm range

Not only the drive and the energy storage system are affected by the electrification of the vehicles, but also a number of auxiliary units. One example of this is the electric refrigerant compressor. The heart of an electric refrigerant compressor is two nested aluminium spirals – scroll stator and scroll rotor. The efficiency of the electric refrigerant compressor depends essentially on how precisely these parts are manufactured. The demands on shape and position tolerances here lie in the range of a few µm. A particular challenge here, for example, is the machining of the “screw”. A defined rectangularity of less than 0.04 mm and a surface roughness (Rz) in the single-digit micron range have to be assured. Despite these demands, the thin walls and the depth of the part, finishing has to be carried out in a single pass. MAPAL has developed an SPM milling cutter with finishing geometry and highly positive rake angle for this application. It ensures low-vibration cutting and has an additional chamfer on the diameter. It can perform the machining of base, wall and chamfer on the front face in a single step. As a result, the close tolerances for rectangularity and surface finish can be reliably achieved.

The tools for machining stator housings, battery housings and the electric refrigerant compressor are successfully used in practice. They show the multitude of processes and solutions that MAPAL offers for machining parts in electrically driven vehicles.

Contact Details

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- conventional milling ( up milling)

conventional milling ( up milling)

Cutter rotation is opposite that of the feed at the point of contact. Chips are cut at minimal thickness at the initial engagement of the cutter’s teeth with the workpiece and increase to a maximum thickness at the end of engagement. See climb milling.

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- micron

micron

Measure of length that is equal to one-millionth of a meter.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.