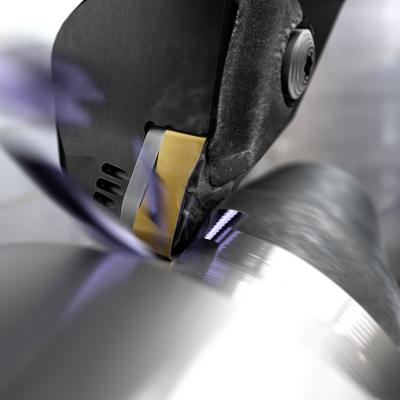

Global metal cutting leader Sandvik Coromant introduces its second generation of CoroTurn® Prime B-type inserts. The new, double-sided negative insert features four cutting edges and is designed for roughing and finishing in steel, stainless and duplex stainless steel, HRSA and titanium.

PrimeTurning™ has, since its introduction in 2017, aptly been called the biggest innovation in turning, since turning. The method enables turning in all directions and is a productive and efficient alternative to conventional machining. The concept comprises the PrimeTurning method, CoroTurn Prime A- and B-type tools and the CoroPlus® Tool Path for PrimeTurning software.

The second-generation CoroTurn Prime B-type tools have undergone a major upgrade. “We are continuously working on developing our PrimeTurning offering,” says Staffan Lundström, product manager at Sandvik Coromant. “The new B-type tools are improved in all aspects to further support all-directional turning.”

A key benefit is that the new insert is negative and double-sided. Four cutting edges — twice the edges compared to the previous insert — allow more cost-efficient machining. The tool is also equipped with a new robust tip seat design, which prevents tool breakage if the insert breaks and enables shifting of feed directions without insert movements. Furthermore, the geometries are updated for better chip control even in very challenging materials, such as duplex stainless steel and ductile steels.

Comprehensive test results have shown productivity increases ranging from 50 percent up to over 100 percent. One example is an automotive customer producing pump housings, where the new CoroTurn Prime B-type inserts with turning grade GC4415, the -M7 geometry and R1.6 mm, gave predictable edge wear and better chip control. Productivity and tool life increased by 115 percent and 200 percent, respectively.

The new CoroTurn Prime B-type inserts are available for external and internal turning in a range of high-performing grades, including the new steel turning grades GC4415 and GC4425. Programming support is available in the most common CAM platforms and with CoroPlus Tool Path for PrimeTurning.

Contact Details

Related Glossary Terms

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.