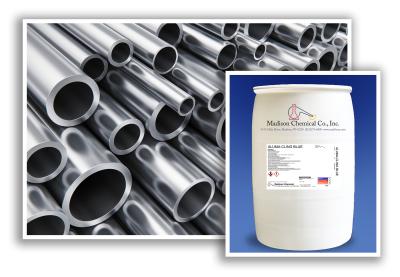

Madison Chemical introduces Aluma-Cling Blue, a moderately acidic, thickened-gel formulation for cleaning aluminum alloys, especially bright, decorative aluminum with no brushing. This phosphate-free product has excellent detergency and rinsing properties and is ideal for 5000 and 6000 series aluminum alloys and stainless steel surfaces.

It effectively removes plasma smoke residue, weld marks, light oxide, and discoloration due to previous processing, and eliminates or greatly reduces streaking, yellowing, whitening and over-etching caused by aggressive acids. Easily applied at full strength by pump, spray or manually wiping or brushing, Aluma-Cling Blue reduces the number of steps and often the manual brushing necessary to obtain a clean, bright aluminum surface.

For best results use Aluma-Cling Blue at full strength (100%) at room temperature. Contact time dependent upon soil loading and application, with 1 to 15 minutes as a reasonable starting point. Longer contact time or reapplication may be required for moderate-to-heavy contaminants. Follow with a cold-water rinse. Optimal results on bright aluminum surfaces are achieved with a high-pressure cold-water rinse.

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- aluminum alloys

aluminum alloys

Aluminum containing specified quantities of alloying elements added to obtain the necessary mechanical and physical properties. Aluminum alloys are divided into two categories: wrought compositions and casting compositions. Some compositions may contain up to 10 alloying elements, but only one or two are the main alloying elements, such as copper, manganese, silicon, magnesium, zinc or tin.

- brushing

brushing

Generic term for a curve whose shape is controlled by a combination of its control points and knots (parameter values). The placement of the control points is controlled by an application-specific combination of order, tangency constraints and curvature requirements. See NURBS, nonuniform rational B-splines.