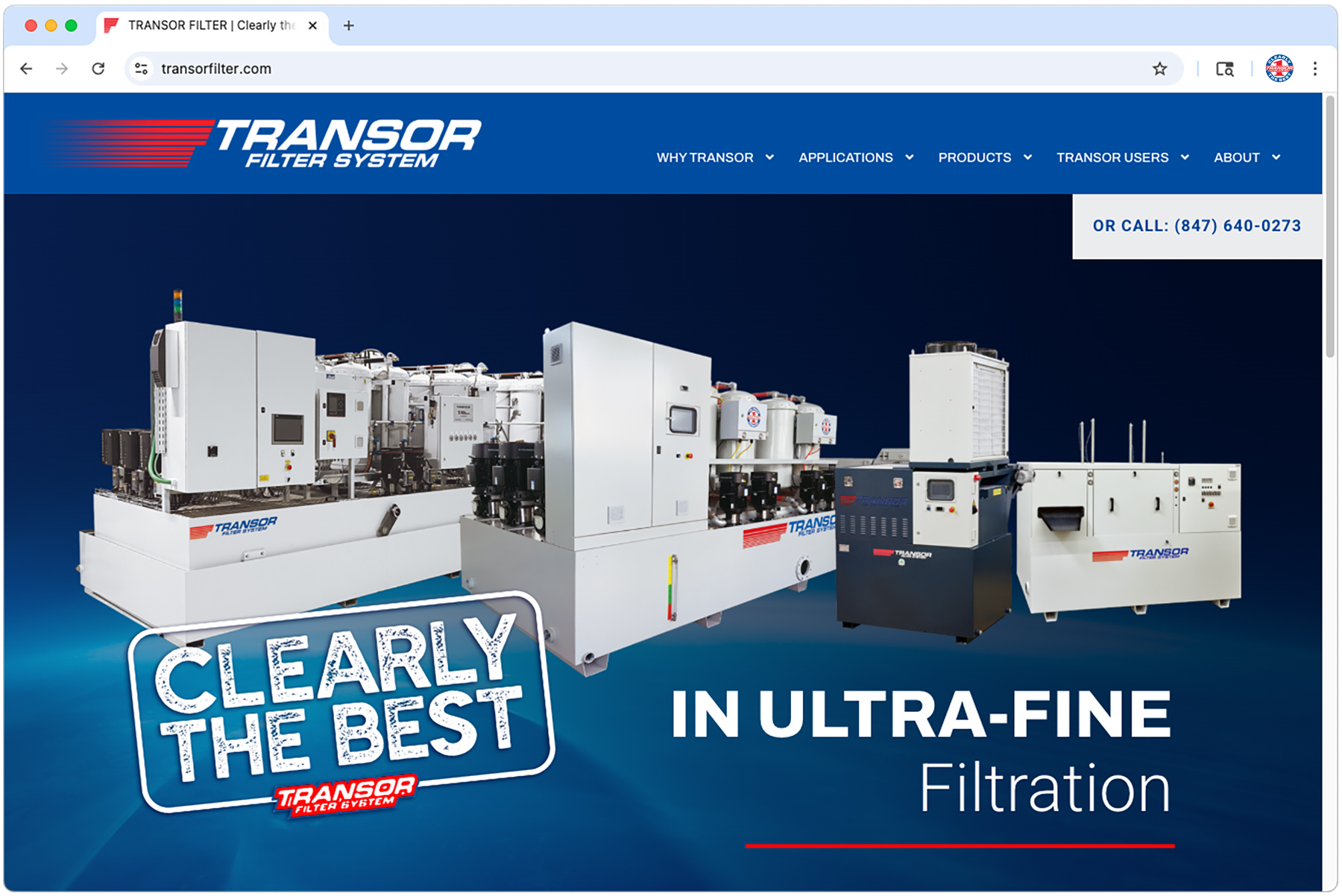

Transor Filter‘s new website has numerous features that details how manufacturers can benefit from Transor’s Ultra-Fine Filtration. Visitors can navigate through useful information for making a considered purchasing decision.

Topics include:

- Cost justification

- Filter applications

- Selecting models and features

- User testimonials

Other topics include: how Transor Filtration Systems deliver faster cycle times, improve product finishes, reduce consumable costs, extend grinding wheel life and provide for a cleaner, healthier work environment.

Based in Chicago, the company performs all final assembly and testing of Transor systems at the Chicago facility, which is also the location of Transor’s service team. This allows for quick response to any customer needs, the company says.

For complete details, phone 847-640-0273, visit the website or email the company.

Contact Details

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.