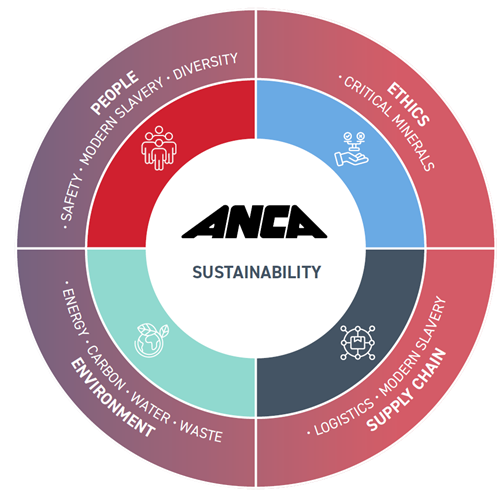

Global technology leader, manufacturing and engineering services, ANCA launched its inaugural Sustainability Strategy 2025–2030, a bold and transformative roadmap that embeds environmental responsibility, innovation, and community impact at the core of its operations.

Designed with the same engineering precision that has defined ANCA for over 50 years, this strategy represents a shift in how the company is shaping the future of advanced manufacturing.

“Sustainability is not a finish line—it’s a commitment to evolving how we think, design, and operate,” said Martin U. Ripple, CEO of ANCA Group. “As engineers, we know progress is built on deliberate, smart steps. We’re proud to take this next step in our journey by integrating sustainability into every layer of our business.”

As part of its environmental commitments, ANCA has aligned its climate goals with the Science Based Targets initiative (SBTi) - a globally recognized framework that helps businesses reduce greenhouse gas (GHG) emissions in line with the latest climate science and the goals of the Paris Agreement.

ANCA has committed to reducing absolute Scope 1 and 2 GHG emissions by 42% by 2030 from a 2023 baseline, and to cutting Scope 3 emissions by 25% in the same timeframe.

The SBTi alignment demonstrates ANCA’s dedication to ambitious, science-driven climate action. Emissions reductions will be achieved through a combination of energy efficiency improvements, adoption of renewable energy, and collaboration across the supply chain.

Strategic foundations

- Governance oversight

An ANCA Sustainability Steering Committee will drive implementation, bringing together leaders from Operations, Finance, HR, and Business Units to ensure sustainability is embedded across decision-making and operations. - Double Materiality Lens

- Guided by a double materiality assessment, ANCA’s strategy focuses on the intersection of business impact and global need—targeting the areas where the company can drive the greatest long-term value.

Key focus areas and targets

Environmental Commitments

- Carbon Emissions: Scope 1 and 2 GHG emissions cut by 42%; Scope 3 by 25% by 2030.

- Circular Economy: Product redesign for recyclability, waste reduction, and closed-loop systems.

People and Community

- Safety: Maintain a LTIFR of 6 or lower; aim for zero harm.

- Diversity & Talent: Expand graduate programs, increase female representation, and build leadership through the ANCA Leadership Framework.

- STEM; Social Impact: Ongoing support for robotics, space, and motorsport university teams, plus charitable programs in Australia, the USA, Thailand, and beyond.

Ethics and Supply Chain

- Modern Slavery: Full compliance with the Modern Slavery Act 2018.

- Sustainable Logistics: Shift to low-emission transport and ethical sourcing through a new supplier code of conduct and sustainability rating systems.

Sustainability through innovation

ANCA’s cutting-edge machines already deliver more sustainable outcomes by design—offering higher energy efficiency, reduced waste, and extended product lifespans. Innovations in IoT, data analytics, and predictive maintenance further reduce operational impact and enhance long-term value for customers.

“Innovation is our DNA,” Ripple said. “Our strategy ensures that every breakthrough doesn’t just drive performance—it delivers lasting environmental and social benefit.

“In our business, microns matter. That same level of precision guides our sustainability approach,” Ripple added. “Every reduction in emissions, every recycled part, every skill developed—it all adds up. Together, with our employees, customers, and partners, we’re not just keeping up with change - we’re driving it.”

Contact Details

Related Glossary Terms

- Rockwell hardness number ( HR)

Rockwell hardness number ( HR)

Number derived from the net increase in the depth of impression as the load on the indenter is increased from a fixed minor load to a major load and then returned to the minor load. The Rockwell hardness number is always quoted with a scale symbol representing the indenter, load and dial used. Rockwell A scale is used in connection with carbide cutting tools. Rockwell B and C scales are used in connection with workpiece materials.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- shaping

shaping

Using a shaper primarily to produce flat surfaces in horizontal, vertical or angular planes. It can also include the machining of curved surfaces, helixes, serrations and special work involving odd and irregular shapes. Often used for prototype or short-run manufacturing to eliminate the need for expensive special tooling or processes.