AdvantEdge 6.0

AdvantEdge 6.0

Machining modeling solutions provider Third Wave Systems offers version 6.0 of its finite element analysis product, Third Wave AdvantEdge.

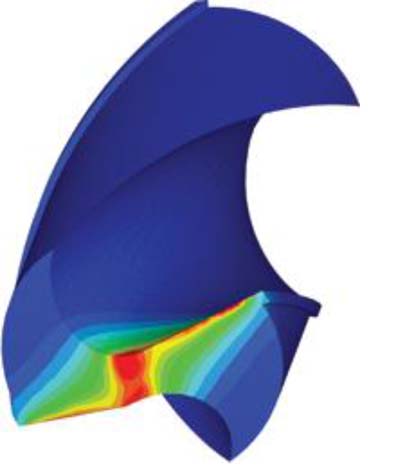

Machining modeling solutions provider Third Wave Systems offers version 6.0 of its finite element analysis product, Third Wave AdvantEdge. Third Wave AdvantEdge is physics-based material modeling technology used by companies that machine metal to optimize their cutting processes and machining strategies, providing detailed information about chip formation, temperatures, stresses, forces, and other material behavior not accessible during trial-and-error tests. The technology has become an invaluable tool for analyzing cutting tool design and performance.

Recognizing the increasing presence of high performance computing hardware, Third Wave focused significant efforts for this release on improving AdvantEdge parallel computing capabilities. AdvantEdge version 6.0 will contain enhanced algorithms that enable the software to more effectively utilize computing cores for significant computing speedups compared to version 5.9. With the release of Third Wave AdvantEdge 6.0, users will also have the opportunity to employ massively parallel computing, designating up to 40 computing cores for any given project. Benchmark testing at Third Wave has demonstrated speedups of between 10 and 20x for milling and drilling, respectively, when comparing serial mode to 40-core computing.

In addition to massively parallel computing capabilities, Third Wave AdvantEdge 6.0 will also contain enhanced material model options for 2D modeling. This new mechanism will enable more accurate characterization of flow stress behavior by allowing users to capture not only isotropic hardening components (currently available within the user-defined yield stress model), but also kinematic hardening components of reverse loading. The user-defined material model enhancement will be especially useful for companies interested in capturing detailed characteristics of workpiece surfaces, and allow users to model more complex deformation modes that could be influential when predicting residual stress. The introduction of kinematic hardening into custom material models is one more step toward giving users the opportunity to create their own comprehensive material models for more accurate results.