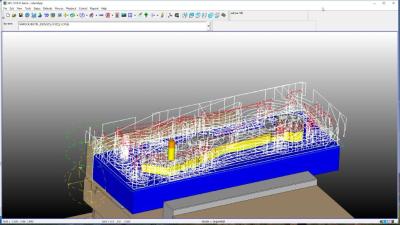

NCCS Corp., developer of NCL multiple-axis machining software that is used extensively in the aerospace, automotive and turbo-machinery industries has further developed an add-on module to NCL for high-speed bulk material removal.

- Increased performance, reduction in costs:

- Shorter cycle times: as much as 3 to 1 (or more) over traditional milling.

- Less wear on your machine.

- Greater tool life

- Efficient toolpaths for open shapes:

- The programmer can cut any combination of part/stock boundaries easily; all open edges are fully leveraged for efficient machining and to minimize plunging into the material.

- Intelligent slot milling and side milling options:

- For softer metals the software provides the fastest possible cycle time and intelligently selects slot milling or side milling to maximize the material removal rate. Feed rates and axial depths of cut are automatically adjusted in slot milling to maintain a constant material-removal rate and can be overridden by the programmer. For harder materials users can configure side milling over the entire toolpath to avoid burying the cutter.

- Fast machining of small pockets:

- The program offers the fastest way to clear out small pockets, as well as efficient specialized tool motion for tight spaces.

- High-feed repositioning with floor clearance:

- The software fully leverages the machine’s capabilities allowing the tool to move safely and as quickly as possible when not engaged in material.Additionally, it clears the floor by a small amount when repositioning at the highest possible speed without dragging it across an already-machined floor.

- Automatic feedrate adjustment:

- The programmer can maintain a more consistent load on the cutting tool with no feedrate optimizer needed; VoluMill toolpaths include precise and automatic feedrate optimization.

These key features of NCL will help companies get the most out of their software investment by increasing programming proficiency in addition to improving the quality and accuracy of their NC programs.

“NCCS is dedicated to constantly improving our software technology, giving the end user what they want,” says Don Schultz, president of NCCS. “The latest release of NCL is yet another example of the entrepreneurial spirit that has made the company successful."

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.