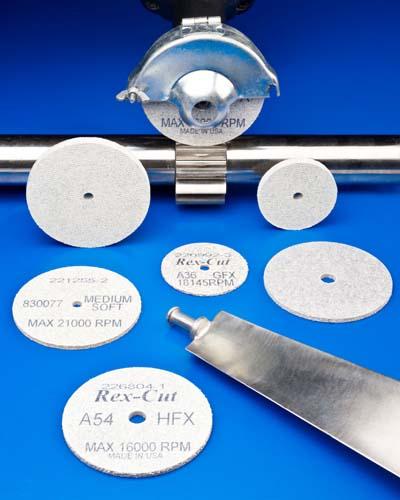

A line of Type 1 cotton-fiber abrasive wheels for grinding, deburring, and polishing that reportedly last up to 10 times longer than unitized wheels is available from Rex-Cut Products.

Rex-Cut Type 1 Abrasive Wheels feature multiple layers of cotton-fiber with aluminum oxide or silicon carbide abrasives laminated, pressed, and bonded into a dense wheel that constantly exposes fresh abrasives while grinding. Comparable to 8 or 9 density coarse, medium, and fine unitized wheels, the cotton-fiber 54, 80, and 120 grit GFX bonded wheels grind faster, last up to 10 times longer, and provide an equivalent finish, claims the firm.

Available in 1" to 4" dia. sizes from 1⁄32" to ½" thick, Rex-Cut Type 1 Abrasive Wheels come in coarse, medium, fine, and very fine grits with soft or hard bonds and are ideally suited for use on aluminum, steel, stainless steel, titanium, Inconel, and other exotics. Applications include aircraft production, oil field pipe thread grinding, and field service repairs.

Contact Details

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- aluminum oxide

aluminum oxide

Aluminum oxide, also known as corundum, is used in grinding wheels. The chemical formula is Al2O3. Aluminum oxide is the base for ceramics, which are used in cutting tools for high-speed machining with light chip removal. Aluminum oxide is widely used as coating material applied to carbide substrates by chemical vapor deposition. Coated carbide inserts with Al2O3 layers withstand high cutting speeds, as well as abrasive and crater wear.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.