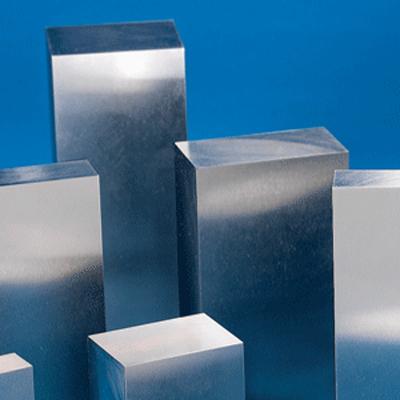

420 Stainless steel from Diehl Steel is a highly-refined mold quality steel that exhibits excellent polishability, good corrosion resistance and good wear resistance. 420 SS from Diehl is an electroslag remelt (ESR), giving it high internal cleanliness and homogeneity. Its high hardness makes it perfect for the manufacturing of plastic molds that require good parting line retention and sealing between colored resins.

Special melting and forging practices result in 420 having a ultra-high microcleanliness and a homogeneous microstructure, according to the company. 420 stainless steel is used in a variety of applications such as ball bearings, gauges, shafts, cutlery, plastic mold cavities and surgical and dental instruments.

Contact Details

Related Glossary Terms

- corrosion resistance

corrosion resistance

Ability of an alloy or material to withstand rust and corrosion. These are properties fostered by nickel and chromium in alloys such as stainless steel.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- microstructure

microstructure

Structure of a metal as revealed by microscopic examination of the etched surface of a polished specimen.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.