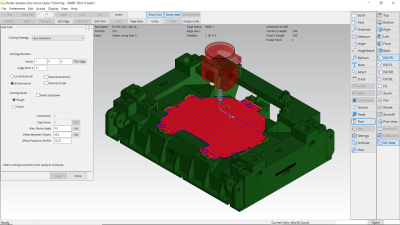

The new release of SMIRT software from Hexagon Production Software features new NC functionality for machining planar surfaces and pockets.

SMIRT NC’s long-standing, easy-to-use drag-and-drop capabilities are now complemented in the 2021 release by two new automated strategies geared toward the high-speed cutting of 2D surfaces on stamping die castings. With a simplified set of parameters and intelligent default values, NC users of all skill levels will be able to create consistent, efficient toolpaths with ease.

Customer requests to generate fast, optimized milling paths for large planar faces with ribs and openings have also been fulfilled.

Enhancements to the Page Manager have improved toolpath management. These include the ability to create named groups and functions for copying and modifying existing toolpaths, which speeds up the process of creating finish paths that use the same tool set-up as the rough paths.

All these new functions increase the efficiency of SMIRT NC, removing some user-intensive practices from the operator’s workflow. The simple user interface, focused to the specific needs of the target market of automotive tool makers, makes the learning curve even faster than before.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- toolpath( cutter path)

toolpath( cutter path)

2-D or 3-D path generated by program code or a CAM system and followed by tool when machining a part.