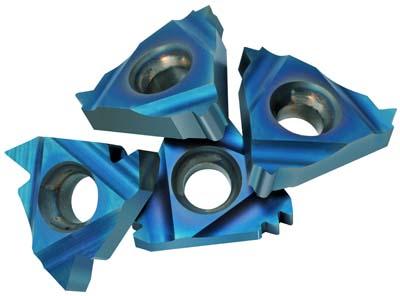

Carmex Precision Tools LLC's new BLU Grade thread turning inserts combine a newly developed sub-micrograin grade with PVD triple layer coating to deliver high strength, longer tool life, more accurate thread and better surface finish, even in the most difficult materials.

Available in a wide range of pitches and threads, BLU grade inserts provide higher value through improved performance, shorter cycle times, and longer tool life.

Contact Details

Related Glossary Terms

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.