Article from The L.S. Starrett Co.

In today’s competitive environment, everyone is on the lookout for ways make their business operations more profitable. Sometimes, simply cutting costs can seem like an attractive way to reach this goal. However, simply reducing the cost of equipment or a process is not a guarantee of success. A better goal is to become more efficient on the job so that operations are more productive, ultimately improving the bottom line.

In the context of bandsaw cutting operations, high efficiency and productivity means keeping the saw running. Downtime associated with blade changes due to wear or breakage, is closely monitored. A considerable amount of time and energy goes into finding ways to reduce downtime. Fabrication and metalworking shops are always looking for a bandsaw blade that will last longer and deliver better quality cuts. While cost is important, it is the cost per cut that really matters. Using a bandsaw blade that lasts longer while making high-quality cuts, to minimize the cost per cut directly correlates to increased productivity.

The service life of a bandsaw blade and the quality of the surface finish made by the cut are not solely determined by the blade manufacturer’s product design. Machine maintenance and operating practices can contribute to, or detract from, this performance. Assuming that the bandsaw is well-maintained and that the operator follows the speed and feed settings recommended by the manufacturer, there is still one more critical step that all too often is skipped: breaking-in the blade.

Virtually all manufacturers agree a blade that has been properly broken-in will have a significantly increased service life. So why would this important step be skipped over? Some feel it is not worthwhile enough to slow down the cutting operation to break-in a blade. However, while the break-in process does involve reducing the feed pressure for the first 25 to 100 square inches of cutting, the extra time is compensated many times over in the extended life span of the blade, in addition to the resulting, improved surface finish in the cuts.

Photos courtesy of The L.S. Starrett Co.

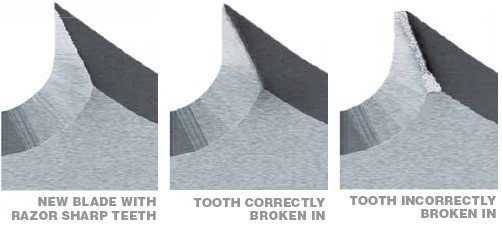

Break-In Visualized

What does breaking-in a blade actually do? New bandsaw blades have very sharp edges on the teeth. That very sharp edge is easily broken and chipped if not broken in properly. Just like a very sharp pencil, the sharp point can break off when you start using it, leaving an irregular, jagged point that doesn’t write well. By gradually increasing the feed pressure during break-in, the sharp tooth edge is evenly honed, leaving a very fine radius to the leading edge of the tooth. This radius allows the chip to shear away from the workpiece more readily, and also gives the required support to the tooth tip, which undergoes extreme forces in the cutting process.

Break-In Process

The process to break-in a bandsaw blade will vary depending on the characteristics of the material being cut. While breaking-in a blade, have the machine running at the normal surface feet per minute.

For softer materials, such as carbon steel and aluminum, adjust the feed pressure to 50 percent of the normal cutting rate for the first 50 to 100 square inches. Then, gradually increase the feed pressure to 100 percent cutting rate.

For harder materials, such as nickel-based alloys, including Inconel, or other difficult materials such as hardened steels, tool steels and stainless steels, adjust the feed pressure to 75 percent of the normal cutting rate for 25 to 75 square inches. Gradually increase the cutting rate to reach 100 percent after 50 square inches. As the feed pressure is increased to the 100 percent cutting rate, be careful to avoid creating vibrations that can occur by increasing the rate too quickly.

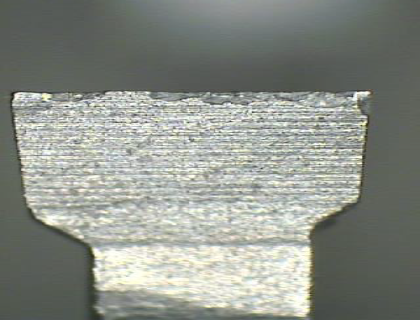

Below is an example of damage to a tooth’s cutting edge that can happen when the proper break-in process is not followed. The photo shows a carbide-tipped bandsaw blades. The blade was run at full speed and with full feed pressure on its initial cut.

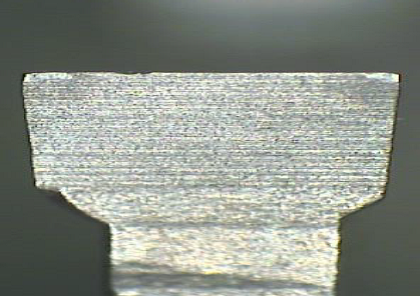

The following photo shows how with a proper break-in, tooth edge damage can be avoided.

Once the teeth are honed and properly broken in, the blade will cut faster, straighter and last longer than an incorrectly broken-in blade. Following a proper break-in process is a simple, easy way to ensure that you’re getting the maximum productivity in your sawing operation.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- bandsaw

bandsaw

Machine that utilizes an endless band, normally with serrated teeth, for cutoff or contour sawing. See saw, sawing machine.

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tool steels

tool steels

Group of alloy steels which, after proper heat treatment, provide the combination of properties required for cutting tool and die applications. The American Iron and Steel Institute divides tool steels into six major categories: water hardening, shock resisting, cold work, hot work, special purpose and high speed.