I’m not a huge fan of machinist’s vises. Even with a speed handle and a couple cups of coffee in your belly, it seems like it takes forever to crank them open wide enough to change a pair of jaws. And once they’re bolted in place, having to tap them in with a hammer and check them with a dial indicator only adds insult to injury. Surely there’s a smarter way to hold parts in a machining center.

According to Doug Fontaine, there is. The national sales manager for CARVEsmart, Cottage Grove, Minn., Fontaine said his company’s vise jaw system increases machine uptime by the equivalent of $2,500 per vise annually, on average, for those that change jaws daily.

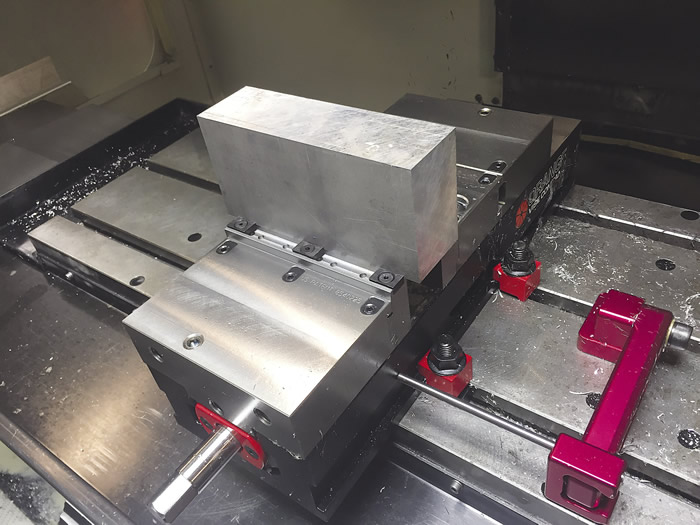

Orange Vise designed a CARVEsmart vise with the master jaw configuration integrated directly into the vise body. All images courtesy CARVEsmart.

“We started the patent work for the CARVEsmart quick-change jaw system in 2010,” he said. “My business partner, Bill Ehnstrom, is a toolmaker who was tired of replacing vise jaws all the time and wanted to spend more time machining parts. He came up with the idea for our master jaws using a dovetailed profile. The system eliminates the need to unscrew the cap screws every time you change jaws, replacing it with a connection that’s solid, fast and true.”

Each 6" CARVEsmart master jaw contains three dovetail clamp assemblies, which grip a replaceable dovetailed steel or extruded aluminum jaw. The two halves of each clamp are connected by a differential screw, with opposing right-hand and left-hand threads at either end. The dovetail assemblies travel in D-shaped vertical slots in the top of each master jaw, at the bottom of which sit threaded holes that engage the opposite ends of the differential screw. Turn the screw’s socket head one direction and the 1018 steel dovetail clamp closes; turn it the opposite direction and it lifts, releasing the replaceable jaw within seconds.

“The design was pretty good right out of the box, but we’ve kept our ear to the ground, looking for feedback from customers,” Fontaine said. “Our Instagram account has been a big help. Because of all the clever ideas received from our customers, we’ve been adding to our product line and making

improvements.”

One improvement was CARVEsmart’s decision to partner with Orange Vise Co. LLC, Union City, Calif., which developed a vise design specifically for the quick-change vise jaws. CARVEsmart is also collaborating with high-density workholding provider Mitee-Bite Products Co., Center Ossipee, N.H., and lists TalonGrip jaws in its catalog.

Fontaine said CARVEsmart jaws are used in two ways. For toolrooms and prototype shops, where jobs typically return to the same machine every time, he recommends one of the company’s steel master-jaw sets. These are equipped with SMARTstop, a slot in the master jaw and dowel pin pressed into the male portion of the dovetail, providing locating repeatability of ±0.0003" (0.0076mm).

CARVEsmart’s Talon Top jaw accommodates multiple Talon Grip clamps from Mitee-Bite.

For production environments, a simpler—if somewhat unorthodox—approach that uses extruded aluminum soft jaws is recommended. “Jobs move from vise to vise and machine to machine in most job shops,” Fontaine said. “So what usually happens with conventional vises is the jaws get machined the first time and then get placed on a shelf when the job is done. When the parts come around again, the next guy has to go find the jaws, open up the vise, clean it out, indicate everything in and set the work offsets. It takes a lot of time and is never as accurate as the first setup on the original vise.”

Fontaine said it saves time to keep the cutting tools needed for jaw machining resident in a toolholder and retain the program used to cut the jaws from the initial job setup. On repeat jobs, simply load a new set of jaw blanks and call up the jaw program.

“Using our aluminum extrusions is far less expensive than making your own soft jaws," he said. "For shops that do make their own, there’s no need to mill bar stock flat or drill mounting holes and counterbore. Just saw the extrusion to any length, stick it in the vise and start machining.”

Related Glossary Terms

- counterbore

counterbore

Tool, guided by a pilot, that expands a hole to a certain depth.

- extrusion

extrusion

Conversion of an ingot or billet into lengths of uniform cross section by forcing metal to flow plastically through a die orifice.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.