Courtesy of Rex-Cut Abrasives

Whether the surface-treatment task involves deburring, blending, grinding, polishing, finishing, dimensioning, patterning or shaping a metal workpiece, there’s a coated-abrasive product available to get the job done. The products include belts, rolls, sheets, pads and flap discs and wheels.

The coated-abrasive name derives from a single layer of abrasive grains being coated, or deposited, onto a flexible or semirigid backing material, using an adhesive, such as resin, to bond the grains to the backing material. This article examines the coating process, various types of grains, or man-made minerals, and backing materials for coated-abrasive products used for several metalworking applications.

Similar to other metal-removal operations, the choice of product depends on the application. “Our salesmen go in, look at the application and decide what the best product to go with is,” said Caitlin Murak at National Abrasives Inc., Lewisberry, Pa. However, operator preference often plays a major role in product selection, she added. “Some people just like a certain brand over another brand and it really doesn’t matter how well it works.” In addition to bonded abrasives and various metalworking products, National distributes an array of coated abrasives, including those from Mirka USA, Norton, Radiac Abrasives and VSM Abrasives.

Applying Abrasives

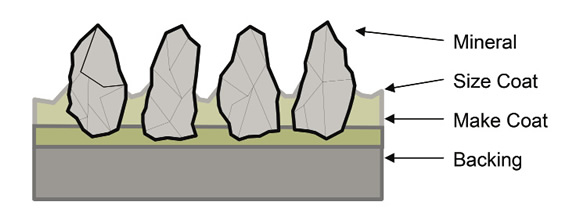

Two layers of resins create the bonding system for coated abrasives, according to a technical paper from VSM Abrasives Corp., O’Fallon, Mo. The first layer is the make, or base, coat, which anchors grains to the backing. The second layer is the size coat, which is applied over the grains to further anchor and stabilize them.

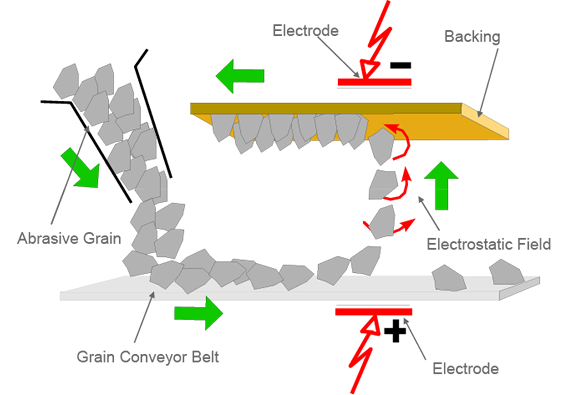

VSM also stated that grains can be applied via the gravity coating process or the electrostatic coating process. In the gravity method, grains drop from an overhead hopper onto the adhesive-coated backing. In the electrostatic method, the adhesive-coated backing and grains pass through an electrically charged field, which propels the grains upward toward the backing that travels upside down above the grains. The grains are then embedded in the adhesive with the sharpest edge of the minerals exposed to ensure uniform cutting.

With these coating processes, grain coverage can be modified to produce open- or closed-coat products. According to information from Norton/Saint-Gobain, Worcester, Mass., an open coat typically has 75 percent of the backing covered with evenly spaced grains, which is ideal for operations where the grinding debris loads or clogs the surface, reducing cutting efficiency and shortening tool life. When making a closed-coat product, the backing is almost completely covered with grain, which is suitable when loading is not an issue and a fine surface finish is required.

Norton/Saint-Gobain’s Director of Marketing and Strategy David J. Long said the abrasive products manufacturer produces large rolls of coated abrasives, called “jumbo rolls,” then converts them to make the required shapes, such as discs, belts and sheets, in a secondary operation.

Grain Types

The primary abrasive grains for metal-working are aluminum oxide, zirconia alumina and ceramic alumina. Less-frequently applied ones include crocus, a natural abrasive of iron-oxide particles used mainly for cleaning and polishing soft metals, and silicon carbide, a hard and brittle grain for nonferrous metals and hard materials.

“The nice thing about silicon carbide is it breaks down very quickly and easily, producing a sharp edge based on its crystalline properties,” said Jim Schnorr, general manager of Wendt USA LLC, Buffalo, N.Y., and president of the Coated Abrasives and Fabricators Association. “The downside is silicon carbide breaks down very quickly and easily, so, in terms of life, it wears out quickly. However, you can essentially grind or cut anything with it, including difficult materials like titanium and carbide.”

Courtesy of Coated Abrasives and Fabricators Association

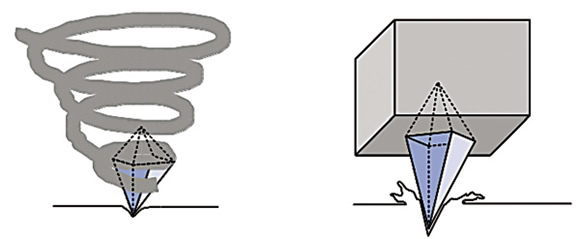

Electrostatic coating is the most widely used process for applying abrasive to the backing of coated-abrasive products. The process leaves the abrasive grains standing upright, perpendicular to the backing, with the sharper ends of the grains pointing up and away from the backing.

Long described Al2O3 as an entry-level abrasive grain that provides a 20 to 25 percent utilization rate. The blocky grain is tough, meaning it resists fracturing, and is suited to grinding materials that are not considered difficult to machine, such as carbon steels. The next level is zirconia alumina, which he noted Norton invented in 1972 and continues to refine. The self-sharpening grain is well-suited for heavy grinding because the controlled fracturing continually produces sharp, new abrading points.

The top tier, according to Long, is ceramic alumina because it cuts at a higher rate compared to the other abrasives. It is a long-lasting, dense abrasive that produces new, sharp cutting edges as micron-sized particles break off during use. “You get about 80 to 85 percent utilization rate of the grain,” he said.

Ceramic alumina is produced via the seeded-gel process, which grows the grains to specific grit sizes, Long explained, whereas zirconia alumina and Al2O3 are “fired,” crushed and screened to achieve the desired grain size. Ceramic alumina and zirconia alumina are sometimes blended, depending on the application. “They work well together for high stock removal,” he said.

Instead of wearing and becoming dull like “old tried-and-true” Al2O3, zirconia and ceramic grains break apart to expose sharp, new cutting edges, Schnorr pointed out. “If they’re used properly, a physical reaction takes place that causes microfractures within the abrasive grains. The microfractures are generated by applying pressure to the abrasive media as it is used.”

Backing Options

Used to carry and support the abrasive grains, backing materials come in four types: paper, film, cloth and fiber. Some manufacturers consider a film, or latex, backing to be almost like plastic paper. The order of that list indicates the relative cost of each type, from low to high, Long said. “In many cases, you want to make sure you need the finishing capabilities that film provides. Otherwise, if you use film on a 60-grit disc, for example, you’re not getting a very good finish anyway so why spend the money on a more expensive film backing?”

Long explained that the grit range for film is usually 220 to 3,000, whereas the range for paper is 40 to 2,000, cloth is 24 to 600, and fiber, being the workhorse, is 16 to 80.

Being the lowest-cost option, paper tends to be the least durable, Schnorr noted, adding that a paper backing is often found in hand-use applications, such as sanding.

However, not all paper backings are equal, as they are divided into six weights designated with the letters A to F. A has a weight of 70 g/m2, B is 100 g/m2, C is 120 g/m2, D is 160 g/m2, E is 250 g/m2 and F is 300 g/m2, with E and F generally considered heavy enough for use as belt materials.

Schnorr said a cotton backing is stronger and more durable than paper, but tends break down fairly easily. “The benefit of cotton is it operates very cool and allows heat to dissipate.”

The stronger cloth materials include polyester and polyester-cotton blends. However, Schnorr added that more durable cloth materials tend to hold heat and can cause other problems, such as leaving residue on the work surface or causing heat discoloration.

VSM Abrasives stated that cloth backings are designated by their flexibility, identified as E (extremely flexible), F (very flexible), J (flexible), T (moderate), X (sturdy) and Y (very sturdy). Mechanical flexing of the coated abrasives creates this range of flexibility, and the types of flexes the company employs include (from stiffest to most flexible) single-, double- and full-flex.

Courtesy of VSM Abrasives

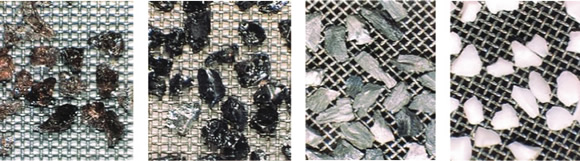

Four types of grains for coated abrasives are (left to right) aluminum oxide, silicon carbide, zirconia alumina and ceramic alumina.

The flexing procedure creates a controlled cracking in the bond, which ensures consistent flex characteristics and enhances stock removal through improved grain regeneration, according to VSM. The flex of a coated-abrasive product is inversely related to product life, and, as a rule of thumb, the company recommends using the stiffest product possible for an application.

When producing fiber backings, several sheets of paper stock are combined via chemicals, heat and pressure in a process called “vulcanizing.” Therefore, some refer to that type of backing as vulcanized fiber.

Courtesy of VSM Abrasives

A typical coated abrasive has a backing, make (base) coat, size coat and mineral.

Courtesy of Superior Abrasives LLC

The spring-like cutting action of a nonwoven abrasive (left) is easier on the workpiece surface than a coated abrasive (right) and is ideal for manual operations that require finesse, according to Superior Abrasives.

Although most applications for paper-backed coated abrasives are performed dry, paper can be chemically treated to make it waterproof. If an application, such as one using a fixed-base belt, requires coolant, the vast majority of Norton’s cloth-backed products are backed with polyester, which is waterproof, as is film. “There’s no treatment for fiber because nobody uses it wet,” Long said.

The backing may be protected when applying coolant, which is done to cool the process or dampen the dust created, but that doesn’t mean the abrasive is protected. Schnorr explained that coolants tend to dissolve the resin bonds that hold the grains in place. “Most coated abrasives do not react well to extended exposure to liquids, moisture or high humidity.”

Switching to Nonwoven

Although available for a couple of decades, nonwoven abrasives use is growing, according to Long. They differ from the traditional definition of a coated abrasive because a nonwoven backing can be impregnated with a layer of abrasives rather than just the top like coated abrasives. “For the most part, a nonwoven is coated,” he said. “It’s just coated on a synthetic nylon backing rather than on a cloth, film, paper or fiber backing.”

With nonwoven abrasives, end users can boost productivity when selecting a high-performance substrate and a premium abrasive, according to Long. “For example, I can offer a Blaze Rapid Strip product, which is a ceramic alumina grain coated onto a highly porous, highly aggressive nonwoven substrate,” he said. “With that particular product, an operator of a right-angle grinder can dramatically improve his wheel life and stock-removal rate over a comparable fiber disc.”

Courtesy of Norton/Saint-Gobain

Norton/Saint-Gobain offers an array of nonwoven abrasive discs.

National Abrasives’ Murak concurred that the nonwoven segment of the abrasives’ market is becoming more prevalent, noting “we mostly sell nonwoven.”

Compared to a bonded abrasive, such as a grinding wheel, which is comprised primarily of abrasive grain, a coated abrasive has only a single layer of abrasive. Therefore, Long noted, it’s not much more expensive to switch to a premium grain, say, going from Al2O3 to zirconia alumina, on a coated-abrasive product. “I can make a premium fiber disc with a lot less ‘premium’ than I can in a premium grinding wheel,” he said. “For example, we don’t even make aluminum-oxide flap discs anymore and hardly anyone else does in the industry. Why would you want to buy a disc for $4 when for $4.50 you could get something that lasts three times as long?”

Nonetheless, extending product life by switching to a longer-lasting grain is not always the best approach to enhancing efficiency, Schnorr pointed out, noting the abrasive is one of the lowest costs in any operation. Therefore, switching the grain to boost the metal-removal rate while achieving a comparable surface finish makes more sense. “What you should be looking for is time savings. Get the job done faster as labor costs tend to have a greater influence on the final cost of the product.” CTE

Supersizing and stearating help maximize product life

Coated abrasives can have coatings. Sometimes referred to as a grinding aid or sizing, a top coat is a chemical coating that can be deposited on a coated abrasive to help dissipate the heat of grinding. To effectively use zirconia-alumina and ceramic-alumina grains, an operator needs to exert a fair amount of pressure when processing stainless steel, for example, Wendt USA LLC’s Jim Schnorr noted. A grinding aid reduces the pressure-generated heat to prevent bluing or other discoloration of the workpiece surface.

Norton/Saint-Gobain’s David J. Long added that a high temperature at the abrasive/workpiece interface heats the bond, possibly causing premature grain release. “The more you can take the heat off of that grain by putting a lubricant on it,” he said, “the more the bond holds that grain in so it continually resharpens and does its work.”

In contrast to coating grains to increase lubricity around the grains—called “supersizing”—Long noted stearating applies a coating between the grains. He explained that supersizing coats the grain itself to lower the grinding temperature on individual grains when processing difficult-to-grind materials, while stearating fills the space between grains with a lubricant to prevent material from the workpiece loading the face of the abrasive tool and to keep the grains exposed. A stearate or other no-fill material, such as a wax, is particularly beneficial when processing soft metals, which tend to load the face.

—A. Richter

Contributors

National Abrasives Inc.

(717) 697-6776

www.nainc.org

Norton/Saint-Gobain

(254) 918-2313

www.nortonabrasives.com

VSM Abrasives Corp.

(800) 737-0176

www.vsmabrasives.com

Wendt USA LLC

(716) 972-0333

www.wendtusa.com

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- aluminum oxide

aluminum oxide

Aluminum oxide, also known as corundum, is used in grinding wheels. The chemical formula is Al2O3. Aluminum oxide is the base for ceramics, which are used in cutting tools for high-speed machining with light chip removal. Aluminum oxide is widely used as coating material applied to carbide substrates by chemical vapor deposition. Coated carbide inserts with Al2O3 layers withstand high cutting speeds, as well as abrasive and crater wear.

- backing

backing

1. Flexible portion of a bandsaw blade. 2. Support material behind the cutting edge of a tool. 3. Base material for coated abrasives.

- bonded abrasive

bonded abrasive

Abrasive grains mixed with a bonding agent. The mixture is pressed to shape and then fired in a kiln or cured. Forms include wheels, segments and cup wheels. Bond types include oxychloride, vitrified, silicate, metal, resin, plastic, rubber and shellac. Another type of bond is electroplated, wherein the abrasive grains are attached to a backing by a thick layer of electroplated material.

- carbon steels

carbon steels

Known as unalloyed steels and plain carbon steels. Contains, in addition to iron and carbon, manganese, phosphorus and sulfur. Characterized as low carbon, medium carbon, high carbon and free machining.

- coated abrasive

coated abrasive

Flexible-backed abrasive. Grit is attached to paper, fiber, cloth or film. Types include sheets, belts, flap wheels and discs.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

- lubricity

lubricity

Measure of the relative efficiency with which a cutting fluid or lubricant reduces friction between surfaces.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- polishing

polishing

Abrasive process that improves surface finish and blends contours. Abrasive particles attached to a flexible backing abrade the workpiece.

- shaping

shaping

Using a shaper primarily to produce flat surfaces in horizontal, vertical or angular planes. It can also include the machining of curved surfaces, helixes, serrations and special work involving odd and irregular shapes. Often used for prototype or short-run manufacturing to eliminate the need for expensive special tooling or processes.

ARTICLES

ARTICLES