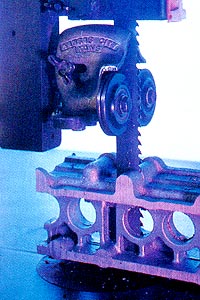

A bimetal bandsaw blade cuts into a difficult-to-machine material. |

|

When metalcutters talk about bandsawing today, they’re talking the language of money—cost per cut, cost/benefit ratios, higher productivity demands, blade specialization, and the bottom line.

Bandsawing today is recognized as an operation that has a profound impact on the bottom line. Nowadays, shops often depend on sawing operations to meet demanding tolerances and eliminate secondary operations such as grinding and sanding. At the same time, shop managers feel the need to perform these operations at lower costs than ever before. Tools such as computer sawing programs coupled with monitoring devices, specialized bandsaw blades, and well-informed technical-service representatives can help meet these demands.

Luckily for users, these tools have undergone changes—some dramatic, some incremental—that now allow machine shops to treat bandsawing as a precision machining step that can contribute to profit.

Computer Assistance

Informational computer software programs are becoming a valuable tool in performing high-precision, low-cost sawing. Informational software for sawing first appeared in the bandsawing arena 10 years ago and has evolved into an effective means of measuring sawing productivity and cost factors.

Massive databases enable the user to input specific cutting conditions for an individual sawing operation, such as the workpiece material and its machinability, shape and size of the workpiece, and whether the workpiece is an individual piece or a bundle.

Using this data, the program can provide a complete set of sawing-parameter recommendations and cost information.

Parameter recommendations include correct blade type, tooth specification, feed rate, cutting rates and times, and new-blade break-in. A cost-cutting analysis is also provided to show specific costs of the operation. By making changes to any of the sawing parameters, the user can determine the effect a given change would have on productivity, in terms of blade life, total cost, or cost per cut, without having to make the change in reality.

Until about two years ago, informational computer programs for bandsawing were somewhat limited in their abilities. They could determine parameters for cutting solid rounds and billets with considerable precision, but they were unable to precisely factor in odd shapes, structural steels, and stacked materials. For these workpieces, the program used general averages, offering helpful but imprecise sawing recommendations in a text-only format.

Today’s advanced software programs can utilize graphics to provide precise instructions on cutting structural materials. To do so, the program must recognize whether the material is standing up or lying down, an impossible task for such programs in the past. Advanced programs “see” how the material is positioned and can measure the exact angles of the material to be cut.

For example, let’s say you want to determine the best way to position an I-beam to maximize the effectiveness of the cut. On the screen, you pick an I-beam from an array of possible workpiece shapes and put it on the machine bed. You can rotate the piece yourself to check other possible positions.

The ideal position for a workpiece depends on your machine and material-handling equipment. Also, the varying thicknesses of a structural piece make positioning important. The bandsaw blade should meet the material wherever the cut will be most continuous throughout. Bandsaw blade life depends in part on proper positioning of the workpiece.

This type of Windows-based software program’s graphics capabilities and user interface make it more flexible than earlier models. In a difficult operation such as sawing structural steel, the user can achieve maximum machine and blade productivity or the most cost-effective cut, whichever is preferred, by simply employing the suggested speeds, feeds, and saw blade.

The Blade

But all the computer advancements in the world won’t amount to much unless saw-blade technology continues advancing as well. In the past, changes in bandsaw-blade design tended to occur infrequently and in “quantum leaps”—from carbon steel to bimetal blades, from standard-tooth to variable-pitch designs, and from zero- to positive-rake teeth. In a variable-pitch design, the teeth are spaced at varying intervals from one another. Variable-pitch blades cut more smoothly and enhance blade life by reducing the harmonic vibration commonly found in carbide-tipped bandsawing. And the introduction of a positive rake angle on the face of the tooth has promoted better penetration of the workpiece material and reduced the force against the tooth. The result has been faster cutting and easier chip formation.

But don’t count on new quantum-leap advancements any time soon. Currently, bandsaw-blade manufacturers are making small, but numerous, incremental changes to the blades.

The incremental nature of bandsaw developments is due largely to the fact that machine shops must deal with tighter tolerances and tougher, more expensive materials. Most bandsaw blades are now being designed to suit specific, individual applications. Therefore, sweeping changes in blade geometries and materials are less likely to occur. A new tooth geometry might significantly improve cutting in one application but could have a negative impact on another.

For example, consider the sawing of an I-beam. When an I-beam is formed, the material is forced through dies and takes on residual stress from the heating and cooling processes involved. During sawing, the I-beam releases the stress and the material expands slightly, narrowing the kerf of the cut. The blade may seize in the narrow kerf. A wider set tooth allows for this narrowing by creating a wider initial kerf, preventing the possibility of the blade seizing. However, in another application, such as the sawing of a solid-shape workpiece, that same wider set tooth might not be necessary, since such narrowing does not happen. In fact, for expensive materials, the extra kerf the wider set tooth creates would be a detriment. A different tooth geometry would be called for.

Tooth configurations, tooth geometries, edge materials, and backing steels for bimetal and carbide-tipped blades are being altered to better penetrate difficult materials. Improvements to some bimetal blades permit successful sawing of H-13, D-2, and P-20 steels; 15-5 PH stainless steel; and Inconel—difficult applications until recently.

Figure 4: Carbide-tipped blades such as this Lenox Tri-Master blade cut a variety of ferrous and nonferrous materials. |

|

HSS blades are fine for sawing mild steels and alloys. But carbide-tipped blades represent the more profitable approach to bandsawing in many nonferrous and some ferrous materials (Figure 4). Use of carbide-tipped blades has doubled in the last two years, probably because they cut faster and last longer than other blades when it comes to sawing materials that generate high heat and wear, including tool steels, aluminum, bronze, aluminum honeycomb, brass, copper, titanium, epoxy resin, carbon graphite, chrome, superalloys, and other new composites used in the aerospace, automotive, and commercial military industries.

Carbide-tipped blades also leave less “ghosting” on the material surface than HSS blades do, so workpieces require less secondary machining. Ghosting is a pattern left by set tooth blades, which have left and right set teeth. As the left tooth enters the material, the blade yields slightly and the tooth bounces, leaving a pattern on the workpiece. Then the right tooth enters and yields slightly, again leaving a pattern. As more teeth enter the cut, the teeth offset each other and there is less bounce. That’s why ghosting occurs mostly at the entrance and exit of the cut; when the blade is close to the center of the material there are more teeth in the cut. Carbide-tipped blades have ground teeth that cut equally on both sides, so they don’t bounce and, therefore, don’t cause ghosting.

The Machine

For further advances with carbide, bandsaw machines also must continue to evolve, providing higher rigidity. Successful cutting with carbide requires machine rigidity to support a good ratio of beam strength to material resistance—a poor ratio will cause the blade to bow and make a crooked cut.

Along with rigidity, feed rates must be made easier to monitor to prevent tooth stripping and improve cut time and blade life with carbide-tipped saw blades. There is still a lot of guesswork going on when it comes to feed rates, since the feed is controlled by an arbitrary value that doesn’t provide exact units of measure.

Computer sawing programs offer a method for predetermining what the feed should be for optimum sawing. Unfortunately, most bandsaw machines have no equipment to monitor and give feedback on what the feed rate actually is at any given time.

Fifteen years ago, most bandsaw machines were pressure-controlled machines (controlling the downward force applied to the saw blade). Operators commonly picked a pressure that led to the fewest problems, even if that pressure setting wasn’t the most efficient one. With an eye toward greater precision, some bandsaw machine manufacturers began making machines that are primarily traverse-controlled. But both pressure- and traverse-controlled machines can be difficult to operate. Because they have no feedback, only trial and error can tell the operator what the best approximate rate is for a specific workpiece material. Different material sizes require different feeds. Billet-cutting machines aren’t much better, because, like pressure-controlled and traverse-controlled bandsaw machines, the feed dialed in doesn’t necessarily equal the resulting feed rate.

Until bandsaw machines offer better feed control, operators will have to depend on other devices to boost precision in the cut. An electronic device designed specifically to measure the feed rate of a bandsaw machine throughout the cut helps tremendously. By alerting the machinist to overfeeding and underfeeding, such a device prevents tooth stripping and shortens cut time. Today, bandsaw machine manufacturers are developing feed monitors to incorporate in their machines.

Technical Services

With the coming of technology such as integrated feed monitors, bandsawing machinery and its uses are becoming more complex. At the same time, blades have become more specialized, the demand for precision in bandsawing has grown, and cost considerations have become more urgent. Each of these trends has increased the need for informed technical service from suppliers of the machines and the blades.

Bandsaw machine maintenance is more important than ever. If a machine is not properly calibrated, or if improperly adjusted guides prevent the blade from approaching the workpiece on a parallel basis, blade performance will suffer. Up to 50% of a blade’s tool life may be lost due to poor setup. This lowers precision and raises costs, a deadly combination.

In the 1970s, domestic bandsaw machine manufacturers were the exclusive providers of technical services for bandsawing operations. That changed over time, however, as an increasing number of bandsaw blade suppliers began developing expertise in machine maintenance, tooth configurations, computerized information programs, monitoring devices, and cutting fluids.

Today, many users seek advice from both machine vendors and blade vendors. A recent independent survey of plant managers, foremen, owners, vice presidents, and quality-control managers in shops that perform bandsawing showed that technical services, communication skills, sawing knowledge, and reliability are the four characteristics that make up a preferred supplier. This seems to indicate that users consider service and recommendations regarding bandsawing techniques to be as important as the quality of the machines and blades. Quality products are expected from a supplier—it’s service that now distinguishes the top suppliers.

Figure 1: Software programs such as SawCalc from American Saw & Manufacturing Co. can identify an array of cost factors in a specific bandsawing application. |

Figure 2: Programs such as SawCalc permit the user to input specific cutting conditions for a bandsawing application. |

Figure 2: Programs such as SawCalc permit the user to input specific cutting conditions for a bandsawing application. |

About the Author

Ann Rooke is communications coordinator with American Saw & Manufacturing Co., East Longmeadow, MA.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- backing

backing

1. Flexible portion of a bandsaw blade. 2. Support material behind the cutting edge of a tool. 3. Base material for coated abrasives.

- bandsaw

bandsaw

Machine that utilizes an endless band, normally with serrated teeth, for cutoff or contour sawing. See saw, sawing machine.

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- bandsawing

bandsawing

Long, endless band with many small teeth traveling over two or more wheels (one is a driven wheel, and the others are idlers) in one direction. The band, with only a portion exposed, produces a continuous and uniform cutting action with evenly distributed low, individual tooth loads. Often called band machining.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- kerf

kerf

Width of cut left after a blade or tool makes a pass.

- machinability

machinability

The relative ease of machining metals and alloys.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- precision machining ( precision measurement)

precision machining ( precision measurement)

Machining and measuring to exacting standards. Four basic considerations are: dimensions, or geometrical characteristics such as lengths, angles and diameters of which the sizes are numerically specified; limits, or the maximum and minimum sizes permissible for a specified dimension; tolerances, or the total permissible variations in size; and allowances, or the prescribed differences in dimensions between mating parts.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- residual stress

residual stress

Stress present in a body that is free of external forces or thermal gradients.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- tool steels

tool steels

Group of alloy steels which, after proper heat treatment, provide the combination of properties required for cutting tool and die applications. The American Iron and Steel Institute divides tool steels into six major categories: water hardening, shock resisting, cold work, hot work, special purpose and high speed.