If you want better holes than a drill can provide, you’re probably in the market for a reamer, a rotary cutting tool used to enlarge and accurately finish holes made by other means. Before beginning the search for a reamer, however, shops should become knowledgeable in certain areas, such as available options, the information needed by potential suppliers and recent developments that might meet needs better than conventional alternatives.

In some situations, it even can pay to take a step back and find out whether a reamer is necessary for a holemaking application.

“Sometimes, the first thing we look at is whether we can hold (the tolerance) the customer wants with a drilling operation,” said Craig Ewing, national drilling product specialist at Iscar Metals Inc. in Arlington, Texas. “If the tolerance is not too tight, there are a lot of things that can be done in the drilling process that will often produce an accurate hole.”

He said drilling can hold tolerances now that in the past could be achieved only by reaming.

“With the old high-speed drilling, you were lucky to get an IT10 tolerance,” Ewing said. “But today, we will typically drill from an IT8 to an IT9 tolerance. If you want to go tighter than IT8, you need to go to reaming,” which easily can attain an IT7 tolerance and in some cases may reach IT5.

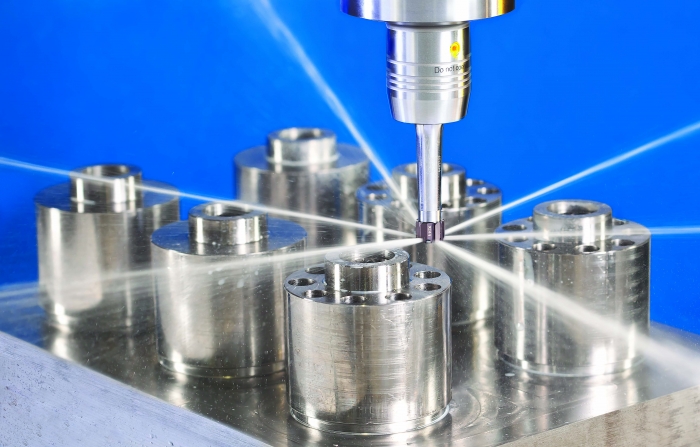

Bayo T-Ream offers interchangeable solid-carbide heads for high-speed reaming applications. A through-the-tool coolant system delivers lubrication directly to each cutting edge. Image courtesy of Iscar Metals

Basic Considerations

If reaming is necessary after all, he said a solid-carbide reamer usually can handle small-to-medium-size production runs. For higher-volume production, he recommends something like Iscar Metals’ Bayo T-Ream, a multiflute reamer consisting of a solid-carbide head mounted to a steel shank. Covering a range from 11.5 mm to 32 mm (0.453" to 1.26") in diameter, Bayo T-Ream offers the speeds of carbide rather than high-speed steel, he said, as well as good repeatability when the head is replaced.

“For medium-to-high-(volume) production runs,” Ewing said, “you get very fast metal removal rates for the reaming operation and also a very high-quality hole in many instances.”

In addition to the choice of material, the performance of a reamer depends on its number of flutes.

“We want to use as many flutes as possible because that helps with the finish,” said John Kiiffner, Northeast director of sales at GWS Tool Group in Tavares, Florida. “The more surface contact we have when reaming, the better.”

The number of flutes that a reamer can accommodate is based on its diameter. For example, he said GWS Tool Group might be able to put up to three flutes on a 2 mm (0.079") dia. reamer, but the number could go up to 11 on a 20 mm (0.787") dia. reamer. He said it’s typically a good practice to put an odd number of flutes on a reamer because this reduces its tendency to lobe a hole.

“With an odd number of flutes,” Kiiffner said, “you get a more precise round hole than if you use an even number.”

Another factor that impacts reamer performance is edge preparation. Ewing said edge prep encompasses the grinding and honing of the cutting edge, the coating used and the lead angle of the reamer. Iscar Metals uses a number of different edge preps for its reamers, depending on the material being cut. Its standard edge prep is a general-purpose one that works for many materials. Normally, however, he said stainless steels and high-temperature alloys require reamers with a special edge prep.

Many times, customers come to GWS Tool Group with tolerances that can’t be achieved even with reaming. In these cases, Kiiffner said, the reamed parts are heat-treated and then put through a honing process to further tighten hole tolerances. To save on the honing process, which is long and expensive, he recommends the use of reaming tools and operations that get holes as close to the application requirements as possible.

Standard or Custom?

One of the most important decisions that shops in the market for a reamer must make is whether to opt for an off-the-shelf or a custom-made tool.

“We do not have any on-the-shelf, standardized product,” said Jamie Dunneback, round tool sales manager at Star Cutter Co. in Farmington Hills, Michigan. “Everything is custom-built to the customer’s requirements and uniquely designed to optimize their process.”

Of course, it takes some time to get a custom-made reamer. While a shop probably can obtain an off-the-shelf reamer in a day or two in many cases, he said the lead time for a custom reamer is roughly six to eight weeks.

A replacement for chucking reamers, PAC reamers are designed to ensure straightness regardless of the pre-drilled hole while maintaining hole size and finish. Image courtesy of GWS Tool Group

In addition, custom reamers cost more than off-the-shelf options. But Dunneback said custom tools are more economical in the long run.

“Generally, because our tools are custom-built and we apply the proper coatings based on the materials used, they will (provide) more linear distance of cut than a standard reamer,” he said. “So they should be less expensive (overall) but with a little higher upfront cost.”

Dunneback also pointed out that if a tool lasts longer in the machine, fewer tool changes are necessary, which slashes costs by reducing cycle time.

Shops that go the custom route should supply as much information as possible about their reaming application to the tooling company they select, said Gary McCarel, application engineer at Star Cutter. For one thing, he and his colleagues need to know the acceptable Cpk, or process capability index, for the application.

“To maintain a Cpk of 1.667, which is pretty much standard in industry, we lose a lot of our size tolerance” for the reamer’s finished diameter, he said. “A part print may say ±13 µm, but for us to run at a 1.667 Cpk, we can only use ±6 µm of that. So sizing is our first concern.”

Makers of custom reamers also must have the application’s position specifications.

“When you rough a hole prior to a finished ream or a finished ream and honing operation, that hole is not necessarily straight from top to bottom,” McCarel said. “So we need to design a reamer that is not only going to maintain circularity, roundness in size and finish but one that will (accurately) cut its own position, top to bottom.”

He said the specified tolerance for positional deviation might be only single-digit microns from the top of a hole to the bottom.

Other particulars needed by Star Cutter designers include an application’s requirements for surface finish and cycle time. Shops should be aware that surface finish affects the cycle time that a reamer can deliver. For example, McCarel said tool designers can shorten cycle times at the expense of surface finish quality by manipulating a

reamer’s flute positions.

Although Star Cutter prefers to design reamers based on application information provided by a customer, the process doesn’t always work that way. In some cases, customers simply ask for something similar or identical to one of their existing tools.

Star Cutter’s fixed-pocket polycrystalline diamond reamers come in both carbide and monoblock steel body styles. Image courtesy of Star Cutter

“They say, ‘We know the tool works, and we’re not looking to change the design. We’re looking for a secondary source or potential improvements based on some simple things that you guys are doing with your coatings, substrates and things of that nature,’” Dunneback said.

In these situations, he said, Star Cutter “will follow the generality of the design coming from the customer specs.”

During subsequent evaluations of the reamers in use, however, company personnel may suggest design improvements to these customers.

Improved Reaming

Although reaming technology hasn’t changed a lot in recent years, there have been developments that reaming tool users should be aware of. One is the increasing popularity of monoblock tools. Kiiffner said “monoblock” refers to the fact that the tools are built on the toolholder, so no clamping is involved.

“Typically,” he said, “when you clamp something, you are going to induce runout.”

So the purpose of creating a one-piece reaming tool is to minimize runout.

The downside, however, is that it’s “very costly” to make tools this way, Kiiffner said.

Another development impacting reamers is the work being done by Star Cutter on the harmonics of tools in use. The objective is to reduce the vibration of tools as they do their job.

“We have people in the field collecting data, and we’ve started assembling a database based on different materials, coatings and constants of kinetic and dynamic friction,” McCarel said. “All these things go into the design of our reamers.”

This database and the mathematical models based on its information allow the company to make predictions that can help stabilize reamers in operation. In some cases, he said predictions are counterintuitive.

“You might think, ‘I have radical vibration at (a certain cutting speed), so I should slow it down,’” McCarel said. “Sometimes, though, you actually need to speed the tool up. You find these zones of calm in the mathematical model, and that’s where you want your tool to be.”

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- lead angle

lead angle

Angle between the side-cutting edge and the projected side of the tool shank or holder, which leads the cutting tool into the workpiece.

- polycrystalline diamond ( PCD)

polycrystalline diamond ( PCD)

Cutting tool material consisting of natural or synthetic diamond crystals bonded together under high pressure at elevated temperatures. PCD is available as a tip brazed to a carbide insert carrier. Used for machining nonferrous alloys and nonmetallic materials at high cutting speeds.

- reamer

reamer

Rotating cutting tool used to enlarge a drilled hole to size. Normally removes only a small amount of stock. The workpiece supports the multiple-edge cutting tool. Also for contouring an existing hole.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

Contributors

GWS Tool Group

877-497-8665

www.gwstoolgroup.com

Iscar Metals Inc.

888-472-2788

www.iscarmetals.com

Star Cutter Co.

248-474-8200

www.starcutter.com