END USER: Mennie Machine Co., (815) 339-2226, www.mennies.com.

SOLUTION PROVIDERS: Engman-Taylor Co. Inc., (262) 255-9300, www.engman-taylor.com; Walter USA LLC, (800) 945-5554, www.walter-tools.com/us.

CHALLENGE: Reduce cycle times, deburring, inconsistent tool life and varying costs.

SOLUTION: A program for productivity services.

Mennie Machine Co. Inc., Mark, Ill., is a Tier 1 automotive supplier that also serves customers in other industries from its 250,000-sq.-ft. production facility. Recently, Mennie was experiencing difficulties meeting its production and profitability goals on a fuel pump housing head, cast from 1722 steel, for an engine manufacturer and major customer.

The main issues included long cycle times, excessive burrs, inconsistent cutting tool life and varying costs, according to Jake Cimei, purchasing manager for Mennie. The company tried to solve these issues internally but had limited success.

Engman-Taylor Co. Inc., Menomonee Falls, Wis., manages the tooling inventory for Mennie. Engman-Taylor believed the Walter Multiply program from its channel partner Walter USA LLC, Waukesha, Wis., could help Mennie achieve the level of success it envisioned.

Jamie Boettcher, district sales manager for Walter, explained: “With Walter Multiply, instead of conventional tool optimization analysis, we put the entire process under the microscope. We combine their production expertise with our knowledge of Walter’s tools and our machining expertise to provide a continuous and sustainable boost in productivity.”

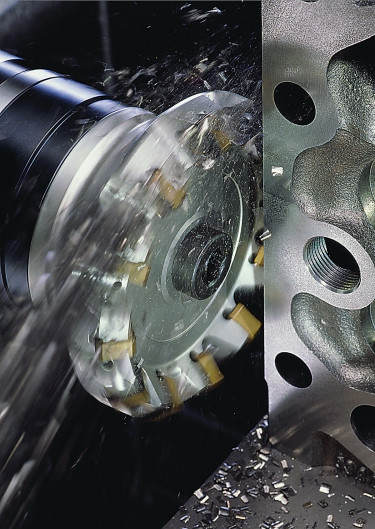

A Walter facemill machines a fuel pump housing head at Mennie Machine. Image courtesy of Walter USA.

The program was brought to bear on two lines that produced variants of the fuel pump housing head and produced 102,000 parts annually. For the first 3 days, Walter watched everything about how Mennie processed the part, including fixturing, machining parameters, toolpaths and chip formation.

Walter also studied available reports and analyzed Mennie’s CNC programs, chips, used tools and cycle times, added Brian Baker, senior applications engineer with Walter Multiply. “Then we came back to our shop in Waukesha and re-created the process,” he said. After the evaluation, the project team decided to pursue a full productivity-solutions package, including programming, and complete part reprocessing with an improved tooling package and new cutting parameters. Baker said the team also proposed providing on-site NC programming assistance and conducting on-site runoffs.

Mennie then established a team to work with Walter. “We quickly knew after the first couple of hundred pieces were run that the project was a success,” Cimei said.

The implementation started with rough facemilling. The operation’s parameters were overhauled to achieve the desired chip formation. In addition, the toolpaths were improved to eliminate inefficient motions. These changes reduced the cutting time for rough facemilling from 52.6 to 22.4 seconds.

New cutting parameters were established for finish facemilling without negatively impacting surface quality, and the cutting tool was changed. These actions reduced the finishing time from 174 to 152 seconds.

Another step was to improve the toolpaths for thread milling by eliminating inefficient motion. Here, the toolmaker used Walter GPS, a programming tool that makes suggestions adapted to a user’s specific conditions. Thread milling time went from 163.8 to 15.2 seconds.

The drilling operations also realized gains by switching to Walter Titex deep-hole drills. To minimize deburring, pecking was eliminated—which also increased tool life—and the speed was reduced at breakout through cross-holes. Drilling time went from 14.2 seconds to 6.4.

“We replaced 31 of the original 48 tools,” Baker said. “With our changes, including installing more-efficient NC programs, Walter Multiply managed to reduce cycle time by 32 percent and reduced tooling costs by 15 percent, or $1.50 per part.”

The total cutting time for the old process was 1,322.5 seconds and involved 54 tool changes, which consumed 378 seconds. The cutting time for the new process is only 642.1 seconds. It requires 50 tool changes, which take only 175 seconds.

Because of the improvements, the number of machines used on the two lines dropped from 11 to eight. Mennie was able to reduce third-shift staffing by five people and eliminate Saturday work on the second line. The scrap and tool-breakage rates were also reduced.

Mennie spent $528,926 for solid perishables for the old process and now spends $502,245 with the optimized process. Overall, Mennie saved $1.4 million the first year by revamping production of the part.

According to Baker, Mennie invited Walter to repeat this cost-savings process with a similar but higher-volume part.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- facemill

facemill

Milling cutter for cutting flat surfaces.

- facemilling

facemilling

Form of milling that produces a flat surface generally at right angles to the rotating axis of a cutter having teeth or inserts both on its periphery and on its end face.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

END USER: Mennie Machine Co., (815) 339-2226, www.mennies.com.

SOLUTION PROVIDERS: Engman-Taylor Co. Inc., (262) 255-9300, www.engman-taylor.com; Walter USA LLC, (800) 945-5554, www.walter-tools.com/us.

CHALLENGE: Reduce cycle times, deburring, inconsistent tool life and varying costs.

SOLUTION: A program for productivity services.