Additive and subtractive manufacturing may be conceptual opposites, but a new partnership aims to show that the two can make a good team.

Two of the partners are New York organizations: the Rochester Institute of Technology (RIT) and Elmira-based Hardinge Inc. RIT researchers are incorporating additive-manufacturing capabilities into Hardinge’s Bridgeport GX 250 5-axis vertical machining center. The goal is to create a hybrid manufacturing system capable of producing more accurate parts at a lower cost than conventional manufacturing methods.

Researchers are adding components that will allow directed energy deposition (DED) within the machining center. DED creates parts using a focused heat source, such as a high-powered laser. This simultaneously melts a substrate and powder feedstock (typically metal powders, but also ceramics, polymers and metal-matrix composites) into the substrate melt pool.

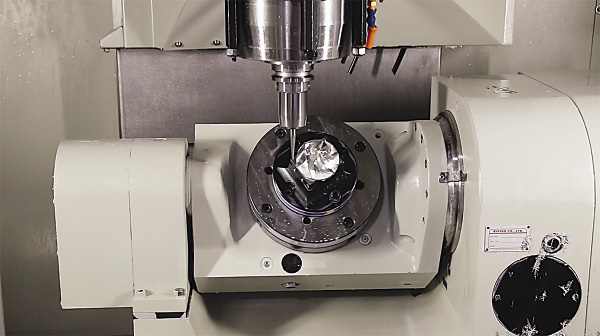

A Bridgeport GX 250 5-axis vertical machining center finish-machines a complex turbine blade. Image courtesy Hardinge.

“There is melting and resolidification, just like you have in welding,” explained Ronald Aman, project leader and assistant professor of industrial and systems engineering at RIT’s Kate Gleason College of Engineering. The small melt pool solidifies in less than a second, he added.

With each pass of the DED head, a single layer of solid material is produced. Layer upon layer build up, eventually resulting in a 3D part.

Work on 3D metal printing is more than a decade old, but reliable part building can still only be done with one material at a time, according to Aman, who hopes that will soon change.

His team is equipping the GX 250 with multiple powder feeders. These can blow a number of different metal and ceramic powders into the DED melt pool. Besides opening the door to a variety of material combinations, Aman said this configuration will make it possible for users to smoothly transition from one material to another while manufacturing parts. As a result, there will be no need for abrupt material-composition changes, thereby eliminating common failure points on parts made of materials with vastly different mechanical or thermal properties.

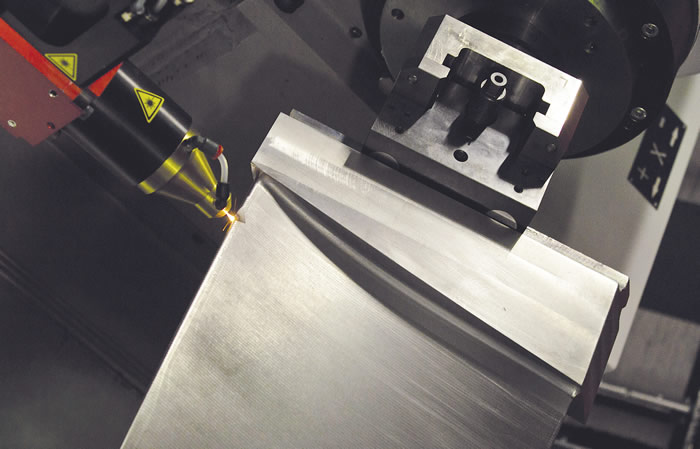

An AMBIT laser cladding head adds material to a damaged turbine blade in a 4-axis machining configuration. Image courtesy Hybrid Manufacturing Technologies.

But why combine additive and subtractive processes? There is normally no way to finish the insides of some parts once they’re built by an AM machine, Aman noted, making it impossible to produce internal geometries that meet aerospace standards or many automotive requirements. But with a hybrid approach, the required internal finishing can be done by iteratively adding material and then machining some of it away.

“Being able to do that while you’re building the part is a huge advantage,” Aman said.

Another hybrid manufacturing advantage is that, unlike purely additive processes, “you don’t have to start with nothing,” Aman said. “You can start with a block of stainless steel, which is much cheaper than the same mass of powder for additive manufacturing, and machine away everything that’s not your part, just like you normally would in a CNC operation. Then if there are complex geometries, you can add them.”

Users of hybrid systems could also start with an existing part, such as a damaged turbine blade. After machining away the damaged area, a hybrid manufacturing system could re-create that area using its additive capability and then finish-machine the added material to meet the required standards.

Aman expects the RIT system to be operational by the middle of March for hybrid manufacturing R&D. Hardinge’s role is to provide field service, as well as design and applications engineering.

The other project partners are IPG Photonics Corp., Oxford, Mass., which provided the system’s laser, and Hybrid Manufacturing Technologies, Dallas and Leicestershire, U.K., which supplied laser cladding heads for the DED process.

One of the partnership’s main objectives is to develop toolpath-generation software for hybrid systems. At present, no commercial software can reliably generate the toolpaths necessary to control additive and subtractive processes in 5-axis equipment, according to Aman.

Nevertheless, hybrid manufacturing systems are already on the market. “I expect that over the next few years, this [technology] will become more mainstream,” he said.

Related Glossary Terms

- ceramics

ceramics

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.