By Unisig

Fast turnaround times and increasingly complex components are standard requirements in the mold industry of today, but achieving the needed precision for high-quality molds can take days or weeks of production time. To meet these growing customer demands with the greatest possible efficiency, high-performance five-axis machining centers are a must for manufacturers. And because modern molds also feature a complex labyrinth of internal coolant channels and

preparation for sensors or other devices, deep-hole drilling is an essential capability to help manufacturers save time and money.

Rather than move molds between machines or to another shop entirely, many moldmakers have begun to integrate multitasking solutions that efficiently can handle both deep-hole drilling and complex machining. In fact, the question isn’t whether your mold shop needs this technology but how much drilling capability your shop warrants.

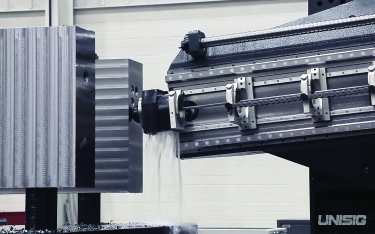

The USC-3M is designed specifically to maximize the performance of modern indexable gundrills. Image courtesy of Unisig

At moderate depth-to-diameter ratios, a high-performance machining center can perform basic gundrilling. But once the ratio goes beyond 40-1, a typical machine struggles even when equipped with a high-pressure coolant system. At best, the deep-hole drilling operation will take a long time. At worst, a tool will break, stopping production and adding expenses. This doesn’t just scrap parts but leads to process instability that inhibits unattended automated machining. To avoid the trouble, many moldmakers send out parts for deep-hole drilling, but this reduces margins and can take an unpredictable amount of time. And when your supplier has inconsistent lead times, so do you.

The obvious solution to these challenges is bringing deep-hole drilling in-house — and with multitasking, putting deep-hole drilling inside the same machines used to produce other features of molds. Indeed, for the most complex molds, simplifying the process with a single-setup approach can reduce the total production time to a fraction of what’s required when sending out parts or moving them between machines. This naturally requires a robust, rigid machine that pairs high-performance milling capabilities with efficient, reliable deep-hole drilling. Probing, presetting, glass scales, angular encoders, pallet changers and other features may be integrated for further process consolidation.

In short, by combining more capabilities in one moldmaking machine, moldmakers will have machines that can serve as effective multitasking platforms and reduce the floor space that mold production takes up. Single-setup machining combined with efficient tooling and advanced fixturing enable significant improvements to quality that in turn sharply reduce post-processing requirements. That means higher throughput and higher profits.

Given the advantages of integrating this kind of multitasking technology, moldmakers should ask themselves what the right level of deep-hole drilling capacity is for their shops. Most manufacturers can find the shop floor space for a compact machine with a universal spindle, for example. But for the most deep-hole drilling efficiency, a dedicated deep-hole drilling spindle is worth the expense for many shops. Striking the proper balance between price and performance is essential, which is why many mold shops choose to partner with original equipment manufacturers that offer a complete range of multitasking machines.

Dual-spindle machines are an investment in the highest throughput and the fastest deep-hole drilling. These machines feature a dedicated geared milling spindle for high-performance machining and a second deep-hole drilling spindle capable of the specialized BTA process. Also known as single-tube system drilling, BTA drilling provides a greater effective range of diameters than gundrilling and can reach feed rates five to seven times faster than brazed gundrills by evacuating chips through the center of the tool with high-pressure coolant. Dual-spindle machines like the USC-M38 and USC-M50 from Unisig substantially minimize unproductive time with options ranging from automatic toolchangers and pallet changers to fully modular fixturing systems.

The USC-3M features robust, high-performance milling combined with Unisig’s indexable gundrill technology for outstanding material removal rates. Image courtesy of Unisig

Moldmakers that recognize the value of deep-hole drilling but just are beginning to integrate the technology at their shops often prefer universal-spindle machines. This cost-effective and easy-to-use approach employs a single spindle for milling and gundrilling. But unlike typical machining centers, universal-spindle machines like the USC-2M and USC-3M from Unisig have been designed specifically to maximize the performance of modern indexable gundrills.

Built around a universal CAT 50 spindle that offers up to 40 hp, the USC-2M and USC-3M feature robust, high-performance milling combined with Unisig’s indexable gundrill technology for outstanding material removal rates. Additionally, a 60-position automatic toolchanger further minimizes nonproductive time to keep parts moving. And programmable pumping systems maximize the performance of water-soluble coolant, allowing shops to perfectly tailor their approach to part production requirements.

For moldmakers integrating deep-hole drilling capabilities into in-house operations, the USC-2M and USC-3M machines are designed for ease of use. Standard Heidenhain TNC 640 controls come complete with human-machine interfaces designed by Unisig to make deep-hole drilling intuitive and approachable. In addition, common options include workpiece and tool probing, along with advanced kinematic optimization cycles, which are leveraged by high-performance shops for unattended machining. A full machine enclosure and simplified maintenance requirements help shops promote operator safety and facility cleanliness.

To expand operations and grow business, mold shops need flexible, efficient deep-hole drilling and milling machines. These must combine robust precision milling, effective gundrilling or BTA drilling capabilities, easy-to-use controls and an automation-ready design. There’s only one solution that can provide all this in a single package: moldmaking machines that offer the multitasking versatility required for success in the mold industry of today.

For more information about Unisig in Menomonee Falls, Wisconsin, call 262-252-5151 or visit www.unisig.com.

Contact Details

Related Glossary Terms

- automatic toolchanger

automatic toolchanger

Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restores the used tool to the magazine and selects and withdraws the next desired tool from the storage magazine. The changer is controlled by a set of prerecorded/predetermined instructions associated with the part(s) to be produced.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- gundrill

gundrill

Self-guided drill for producing deep holes with good accuracy and fine surface finish. Has coolant passages that deliver coolant to the tool/workpiece interface at high pressure.

- gundrilling

gundrilling

Drilling process using a self-guiding tool to produce deep, precise holes. High-pressure coolant is fed to the cutting area, usually through the gundrill’s shank.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- modular fixturing

modular fixturing

System in which fixtures are constructed from standardized, reusable components. Fixtures are assembled and disassembled quickly. Basic styles are subplate, dowel-pin and T-slot. See fixture; modular tooling.

- multifunction machines ( multitasking machines)

multifunction machines ( multitasking machines)

Machines and machining/turning centers capable of performing a variety of tasks, including milling, drilling, grinding boring, turning and cutoff, usually in just one setup.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.