HORIZONTAL MACHINING CENTER IS FLEXIBLE: Heller Machine Tools offers the FP 4000 5-axis HMC with twin drives in the Z-axis. Workpiece capacity is 1,400kg (3,086 lbs.) , and the X-, Y- and Z-axis work envelope measures 800mm × 800mm × 1,045mm (31.50"×31.50"×41.14"). The machine comes standard with a 10,000-rpm spindle and HSK 63 spindle taper. According to the company, temperature does not infl uence the machine’s precision, because of its construction and thermal stability. The machine is available with a 54-, 80-, 160-, 240- or 409-place tool magazine.

Heller Machine Tools

www.heller-us.com

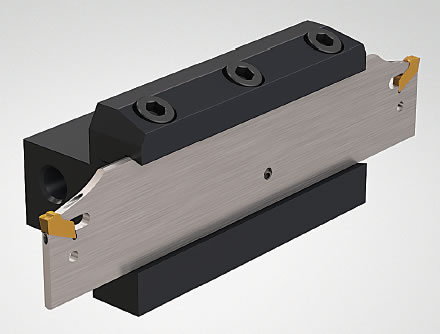

PARTING-OFF SYSTEM OPTIMIZES COOLANT DELIVERY: Seco Tools LLC’s 150.10-JETI parting-off system incorporates HSS blades, Jetstream Tooling technology and tool blocks with coolant inlets. Together, these elements provide high-pressure coolant a straight path to the cutting edge and an optimized means for effectively penetrating the friction zone between the cutting edge and workpiece, according to the company. The HSS blades, available in 20mm (0.787") and 25mm (0.984") sizes, maximize insert stability. The blades accommodate insert widths from 2mm (0.079") to 6mm (0.236").

Seco Tools LLC

www.secotools.com

OIL SKIMMER TARGETED FOR SMALL SHOPS: The Mini-Skimmer R.S. from Wayne Products is a belt-type oil skimmer that has a housing that measures 3"×3"×2.75" (76.2mm × 76.2mm × 69.8mm) and collects more than a quart of oil per hour. The liquidtight housing is made of anodized aluminum. It has an on/off switch, allowing users to monitor its activity, and is lightweight, enabling transportation between machines. It comes with a stretch-resistant, fi berglassreinforced cogged belt.

Wayne Products

www.mini-skimmer.com

CNC FEATURES MULTIPLE ADVANCES: Fagor Automation USA says the CNC 8060 T meets the requirements of production lathes, high-speed machining centers and machines that require high accuracy and high-end features. Advances include a touch screen, high-defi nition graphics, pop-up-based browsing and more than 500 Mb of memory standard, expandable via Compact Flash. Users can choose from four programming methods: standard ISO language, parametric language, ProGTL3 language and IIP interactive language (interactive icon-based pages).

Fagor Automation USA

www.fagorautomation.com

Contact Details

Contact Details

Contact Details

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flash

flash

Thin web or film of metal on a casting that occurs at die partings and around air vents and movable cores. This excess metal is due to necessary working and operating clearances in a die. Flash also is the excess material squeezed out of the cavity as a compression mold closes or as pressure is applied to the cavity.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- work envelope

work envelope

Cube, sphere, cylinder or other physical space within which the cutting tool is capable of reaching.