The promise of the industrial internet of things (IIoT) is that every aspect of the manufacturing process, from product design to delivery, can be digitized, networked, monitored and, based on the collected data, improved. The challenge is that it’s hard to realize a system that effectively can communicate with such a wide array of systems and devices. They perform a broad range of tasks, were made by various manufacturers and differ in age.

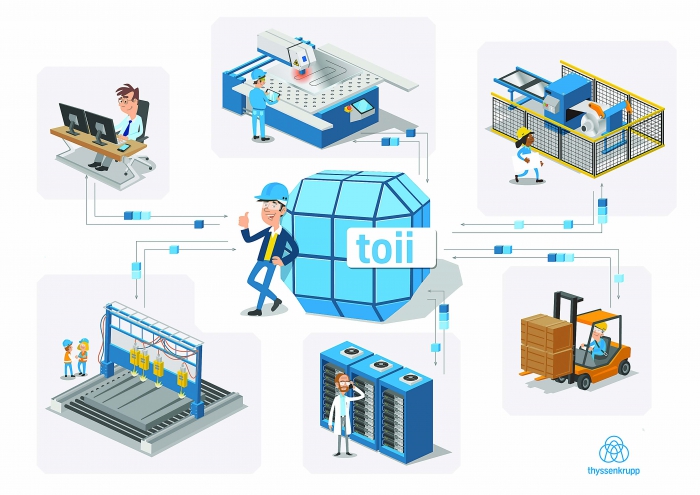

This thyssenkrupp diagram shows the reach of the toii platform. Image courtesy thyssenkrupp Materials Services.

For its own in-house use, thyssenkrupp Materials Services GmbH believes that it has created a system that does so: the toii Platform. This makes it possible to digitally connect bandsaws and bending machines; mobile objects, such as cranes; complex production facilities, such as slitting and cut-to-length lines; and sophisticated processing and machining solutions. The platform allows machines to share data and communicate with one another and IT systems.

It also is designed to simplify data analysis through a clear, easily navigated system accessed with the click of a mouse, the company reports. Processes can be planned and coordinated optimally and flexibly—across locations worldwide. The platform is highly scalable and can integrate up to several hundred machines a year.

“We’ve created an end-to-end solution that is tailored specifically to our needs. It will enable us to accelerate the automation of our production operations and make our processes much more efficient,” said Hans-Josef Hoss, thyssenkrupp Materials Services board member.

The system has been successfully used at various thyssenkrupp facilities in Germany, and plans are in place to deploy it in the U.S. and U.K. as well. According to Michael Ridder, the company’s head of communications, all data affiliated with the platform is hosted on a central server in Germany. To comply with all data protection law requirements, local servers will also be used for the system in the U.K. and U.S. as part of the platform’s rollout.

For more information about thyssenkrupp Materials Services GmbH, Essen, Germany, visit www.thyssen

krupp-materials-services.com or call +49 (201) 844-534416.

Contact Details

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.