Floor Dry is piled around the base of the machines. Oil drips from the ceiling. Grinding dust collects in your coffee cup. A face full of mist greets you every time you open the machine door. This is the environment in which I learned machining 30 years ago. Back then, new machines were simply set on the floor, plugged in and given a quick leveling. Machine foundations were rare and temperature control was at the whim of whoever operated the loading dock door.

Courtesy of TOMZ

TOMZ Corp. has invested at least $150,000 in equipment to improve air quality, including this air filtration system. The investment returns about $5,000 a week in reclaimed cutting oil.

Shops today are more aware of environmental conditions. Mist collectors and electrostatic air cleaners are not uncommon and many manufacturers realize there’s little chance of attracting high-caliber work from customers when the shop is a pigsty. Many also recognize that proper environmental controls and a good machine foundation are important to accuracy—that holding a few tenths tolerance or imparting a mirror finish is all but impossible if the floor shakes like Elvis Presley every time the Union Pacific rumbles past.

But the sad truth remains that there are still too many shops ignoring air quality, temperature and machine isolation. This is bad for machines, their operators, part quality and, ultimately, the bottom line.

Take a Deep Breath

Let’s start with air quality. Royal Products, Hauppauge, N.Y., has sold the Filtermist product for more than 30 years, yet Tom Sheridan, vice president of marketing, estimates fewer than 25 percent of machine tools have a mist containment system. “We’re still amazed at the number of people who approach us at trade shows who had no idea there are products available to take care of the mist and smoke generated by machine tools,” he said.

The Occupational Safety and Health Administration is partly to blame. The same people who mandate steel-toed boots and ear protection apparently don’t get too excited about shop air quality. “OSHA offers a guideline of 5 mg of particulate matter per cubic meter of air, but there are no actual regulations,” Sheridan said.

Lung damage, slippery floors, fire hazards, lost cutting fluid—there are many good reasons to keep air clean. Sheridan recommends exchanging the air inside a machine enclosure five times each minute. That might cost a few thousand dollars on a typical 8 " (203mm) CNC lathe or 20 "×40 " (0.5m × 1m) machining center. Too much money? Think about profits. “We’ve actually found shops where the operators were dialing back the speeds and feeds to reduce the amount of mist being produced,” he said.

Production efficiency aside, human help is a shop’s most important asset. “Some shops use climate control as a way of attracting good talent,” Sheridan said. “They want to give their employees a comfortable, healthy place to work.”

Courtesy of Royal Products

A Royal Filtermist removes mist on a Haas CNC lathe.

Scott Hilton, project manager at Machine Specialties Inc., a contract machining and metal finishing company in Whitsett, N.C., said he’s the person to call if you need something, so when MSI’s original owner called him 20 years ago and said he wanted his shop to look like a place people would want to work, Hilton got busy.

Over the years, he’s covered the floors with 3⁄16 "-thick epoxy and beefed up the HVAC systems, including installation of several air filtration units from Sanford, N.C-based Trion Air Purification Systems. “We have two types of air cleaners,” he said. “For the Swiss CNC lathes, we have electrostatic precipitators for oil and smoke. On the mills and other machines that run water-soluble coolant, we use Trion’s HEPA-equipped Air Boss systems.”

Hilton said the shop’s “eat-off-the-floor” cleanliness has attracted new customers, made machine maintenance easier and reduced operating costs, saving the company $20,000 annually in recovered cutting fluid. “We have 57 CNC machines—Swiss lathes, multipallet horizontals, 5-axis vertical machining centers and so on, running 24/7,” he said. “We do aerospace and medical work, and our customers expect the shop to be clean. But, just as importantly, this is our facility and that’s how we want it to be. It’s a mindset.”

Here Comes the Sun

Another shop with that mindset is Berlin, Conn.-based TOMZ Corp., a manufacturer of medical and aerospace components and customer of machine supplier Methods Machine Tools Inc., Sudbury, Mass. TOMZ Vice President Tom Matulaniec explained that, like MSI, it has installed electrostatic air cleaners for its machine tools, ducting them to a centralized unit. “We’ve easily invested $150,000 or more on air quality,” he said. “Aside from providing clean air, that investment probably returns nearly $5,000 a week in reclaimed cutting oil.”

Courtesy of TOMZ

TOMZ air-conditions its shop to a consistent temperature of 72° to 74° F (22° to 23° C) year round and installed 4 '×8 ' (1.2m × 2.4m) windows along the roofline to bring in natural light.

The company also air-conditions its shop to a consistent temperature of 72° to 74° F (22° to 23° C) year round. Matulaniec said: “We hold tenths on some of our jobs. Even with the constant air temperature, you still have to let the machines warm up after they’ve been sitting all weekend. And we’ve noticed that the machine closest to the shipping area gets a little cranky if you open the loading door, especially in the wintertime. Temperature is critical with tolerances this tight.”

In addition to its investment in air-temperature and quality control, TOMZ recognizes the human side of the equation, installing 4 '×8 ' (1.2m × 2.4m) windows along the roofline to bring in natural light. “We have guys out there working 10 or 11 hours a day,” Matulaniec said. “For much of the year, they clock in when it’s dark and go home when it’s dark. The windows make the environment a little better for everyone.”

Despite the tight tolerances, Matulaniec said TOMZ has not seen the need for special machine foundations. Until recently, that is. “We have all of our equipment bolted to the floor,” he said. “This is primarily to maintain alignment and keep it from moving around. We never had any trouble with vibration, then this week the city began repaving the street next to our building. You can feel it in the floor, and the machines can feel it too. We haven’t been able to run any close-tolerance work since they started doing that.”

Shake it Up

Keith Leatherwood, vice president of sales at Vibro/Dynamics Corp., Broadview, Ill., which has manufactured machine mounts and vibration isolators since 1964, has a solution to Matulaniec’s problem: pour a slab. “Standard production floors are designed to support the weights of people, racks, tables and forklifts, not machine tools,” he said. “A true machine foundation can support a much higher load in a smaller area.”

There are many factors to consider. Leatherwood said these include accuracy requirements, weight and size of the machine tool, temperature and soil conditions, and proximity to railroad tracks. Ultimately, movement in the concrete beneath a machine tool negatively impacts its alignment. Ballscrews bend, machine frames twist and parts go out of whack. That’s bad news whether you’re making standard nuts and bolts or bone screws for spinal implants.

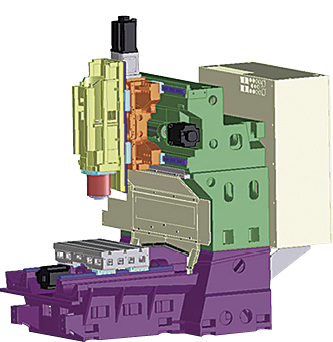

Courtesy of Okuma America

Gantry-style frames used on vertical machining centers are more thermally stable than traditional C-frame style machines.

Granted, reinforced machine foundations are a no-brainer in ultraprecision machining environments and for large machines, such as boring mills and heavy stamping equipment. Yet most shops have neither the cash nor ability to chop up the floor and pour a couple feet of rebar-reinforced concrete beneath each machine.

Leatherwood suggests elastomer mounts as a simpler and more cost-effective way for shops to isolate all but the most demanding machine tools from external vibration. These devices for CNC lathes, mills and EDMs are rubber hockey puck-like devices that replace a machine’s standard leveling pads.

For roughly 1 percent of the machine price, elastomer mounts eliminate vibration from air compressors, roaming forklifts and nearby road construction, according to Leatherwood. Buyer beware, however, because not all rubber is up to the task. “Metal pads are all created equal, but not so with elastomers,” he said. “Cheaply made mounts may creep or settle over time, doing more harm than good.”

Keep it Steady

Gary Snow knows the right environment for a machine tool. As principal engineer for Okuma America Corp., Charlotte, N.C., Snow’s seen the best and worst of shops. “Some factories don’t have any climate control,” he said. “This is especially true in developing countries, but even here in the U.S. you’ll see shop floors where it’s 100-plus degrees F during the summer and there’s mist and oil flying all over. This is hard on the machines and hard on the operators.”

In an ideal world, machines would be kept at 68° F ±3° F (20° C) at all times, Snow explained. The air would be clean enough to keep electronics and operators happy and relatively dry to prevent rust and corrosion. Barring an isolated machine foundation, the floor would be concrete at least 6 " (152.4mm) thick and the machines anchored, minimizing machine movement. Machine builders, however, know that the world in which machines and people coexist is far from perfect.

“At least some of the problems caused by less-than-ideal environments can be overcome by machine design and operation,” Snow said. Gantry-style machines, for example, are inherently more stable than C-frame machines. And operators have long known to let a machine warm up while they get their morning cup of coffee and keep the loading doors closed on wintry days. “If you’re unable to maintain climate control in your shop, at least try to minimize the rate of temperature change—the delta—as best you can.”

You may not think a hunk of iron and sheet metal weighing 15,000 lbs. (6,804 kg) or more could be affected by an open loading door, but even the most robust of machine tools will suffer some degree of frame twist and column droop during a sudden temperature swing. “Cast iron is very elastic,” Snow said. “On a machining center, this can affect true position and Z-axis height. Close-tolerance turning and boring on a lathe is likewise problematic without stable air temperatures.”

Similar problems crop up with poor machine foundations. “Machines these days are heavy and fast, with rapid traverse speeds exceeding 600 ipm. This introduces forces and stresses on the machine, which carries all the way down to the leveling pads,” Snow explained. “Without a proper foundation and anchoring, you’ll find the machine’s geometric properties—and the positional relationship between the axes—will degrade over time. You’ll be left struggling to maintain part accuracy, and you will incur downtime from frequent releveling of the machine tool.”

A Perfect World

Scott Walker, president of Mitsui Seiki (U.S.A.) Inc., Franklin Lakes, N.J., understands the importance of sound foundations and proper temperature control. The company’s manufacturing plant in Kawajima, Japan, was built to mind-boggling environmental standards. The 180,000-sq.-ft. facility has five separate assembly bays, all temperature controlled to 23° C ±0.4° C (73° F) and no more than 0.2° C variation floor to ceiling. The floor of each bay is an isolated concrete slab 1,200mm (47¼ ") thick, supported by 1,700 concrete pylons, 3 ' (0.9m) in diameter × 120 ' (36.6m) deep.

“There are only two facilities like this in the world,” Walker said. “The other is the Yasda factory in Okayama. We are the only two builders capable of holding better than 20μm positioning accuracy throughout the machine cube.”

Perhaps your shop doesn’t need a space similar to that, but a company that builds parts for airplanes does. Walker said aerospace manufacturing is a key industry that frequently requires environments approaching Mitsui-Seiki’s high-tech factory.

“If, for example, you’re building a gearbox that starts a jet engine, the input shaft site might spin at 18,000 rpm and the output is running somewhere around 45,000 rpm,” he said. “You’ve got eight or nine gears in there, each supported by bearing sets that, when assembled, meet stack-up tolerances under 20μm. Get it wrong and that gearbox will smoke on takeoff—never a good thing on an aircraft. To be successful, you need an environment that complements the work you’re doing and the equipment you’re doing it on.”

Now that you have something to think about as you’re boarding a plane, consider your shop. Are you preventing machinists from breathing in air more toxic than the surface of Mars? Is the shop kept cool, preferably somewhere in the low 70s and dry like an Arizona winter? What about vibration—can you still hold tenths on a bore even when the air compressor kicks in or the shipping guy does donuts with the forklift in the parking lot? If the answer is no, maybe you should investigate. Your machines—and their operators—will thank you. CTE

Contributors

Machine Specialties Inc.

(336) 603-1919

www.machspec.com

Mitsui Seiki (U.S.A.) Inc.

(201) 337-1300

www.mitsuiseiki.com

Okuma America Corp.

(704) 588-7000

www.okuma.com

Royal Products

(800) 645-4174

www.royalprod.com

TOMZ Corp.

(860) 829-0670

www.tomzcorp.com

Vibro/Dynamics Corp.

(800) 988-4276

www.vibrodynamics.com

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting fluid

cutting fluid

Liquid used to improve workpiece machinability, enhance tool life, flush out chips and machining debris, and cool the workpiece and tool. Three basic types are: straight oils; soluble oils, which emulsify in water; and synthetic fluids, which are water-based chemical solutions having no oil. See coolant; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- inches per minute ( ipm)

inches per minute ( ipm)

Value that refers to how far the workpiece or cutter advances linearly in 1 minute, defined as: ipm = ipt 5 number of effective teeth 5 rpm. Also known as the table feed or machine feed.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- rapid traverse

rapid traverse

Movement on a CNC mill or lathe that is from point to point at full speed but, usually, without linear interpolation.

- shop air

shop air

Pressurized air system that cools the workpiece and tool when machining dry. Also refers to central pneumatic system.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

ARTICLES

ARTICLES