In honor of Women’s History Month, CTE remembers groundbreaker Catherine “Kate” Anselm Gleason (1865-1933). During the restrictive culture of her time, she helped shape the global cutting tools industry as a sales engineer for her family’s gear cutting machinery business.

In honor of Women’s History Month, CTE remembers groundbreaker Catherine “Kate” Anselm Gleason (1865-1933). During the restrictive culture of her time, she helped shape the global cutting tools industry as a sales engineer for her family’s gear cutting machinery business.

In doing so, Gleason prompted admiration for her warm, personal approach and flamboyant style, as well as the opprobrium of certain members of her family.

Now named Gleason Corp., Rochester, N.Y., what started as a one-person business recently celebrated its 150th anniversary. Today, the multinational corporation produces advanced gear cutting and grinding machines—and the cutting tools and grinding wheels they use—to produce the gears found in an array of applications.

The company began humbly in Rochester in 1865. Kate’s father, William Gleason, was an immigrant from Ireland. He opened a machine shop where he produced metalworking tools and machines, such as engine lathes and planers.

In 1874, William invented and patented the bevel gear planer, a type of machine that opened vast new possibilities for the transmission of motive power. Bevel gears are cone-shaped and make it possible to transmit power at a 90° angle from the drive shaft of a car to its rear wheel axle (see “Bevel Gears: Then and Now” on this page).

Kate’s Involvement

After her older stepbrother died, 11-year-old Kate volunteered to help with bookkeeping at her father’s machine shop. Kate must have inherited some of her father’s mechanical ability. By 14, she was running the business office and reading engineering books at night.

In 1884, Kate entered the Sibley College of Mechanical Engineering and Mechanic Arts at Cornell University, making her one of the first women to study engineering in the U.S. Although she never earned a degree because of financial problems at home, she continued to learn on the job. She also took courses at the local Rochester Athenaeum and Mechanics Institute (later renamed the Rochester Institute of Technology).

A letter to her brother, James, written in 1889, shows Kate’s understanding of machinery and sales. She described in detail a taper-attachment lathe requested by a customer, then advised James on how to make the sale.

By the time she was 25, Kate was officially named secretary-treasurer of the company, becoming a stockholder along with her two younger brothers. Unfortunately for Kate, family relationships began to disintegrate because of her unconventional ways.

Kate lived in the Victorian era, when women lived highly restricted lives. Yet in 1888, she traveled alone for a 4-day sales trip to Ohio. Though worried about how she would be treated as a single woman doing business in industrial shops, she wrote to her brother that “in every case I was treated with the most distinguished consideration.”

Soon, Kate, who has been described as “nobody’s fool when it came to machine tools,” became the company’s chief salesperson, traveling across the country to promote products.

In 1893, during an economic downturn in the U.S., Kate decided to sail to Europe to fill her order book. Some people were shocked at the 28-year-old single woman’s decision to travel internationally without an escort and not knowing anyone at her destination.

Taking only $200, a black cashmere dress and several letters of introduction, she boarded a steamer for the 2-month voyage across the Atlantic, accompanied by 14 men and some cattle. The men took turns strolling with her around the deck for recreation.

The trip was a huge success. It made Gleason one of the first manufacturing companies to expand to Europe. Kate obtained orders for Gleason machines in Scotland, England, France and Germany, establishing a tradition of international marketing that undergirds the company to this day.

Though customers appreciated Kate’s salesmanship, her younger brothers, who ran the manufacturing shop, did not take kindly to her business methods.

“Kate was a rather self-assured, domineering, hard-to-get-along-with woman,” said Janis Gleason, wife of Kate’s great-nephew. “She knew her customers. She listened to them, and she understood their needs. She would come back to the shop and suggest that her brothers be a little more flexible, and that didn’t go over very well.”

Ultimately, the personality clash with her brothers came to a head. Kate chose to leave the company to which she had dedicated her life.

Soon after, she was given the opportunity to manage another Rochester machine tool firm, which she returned from bankruptcy to profitability within a year and a half. She eventually became involved in running a bank and other business ventures.

Through the years, she also supported the women’s suffrage movement (her mother was Susan B. Anthony’s friend) and a host of charities.

Kate’s Honors

Kate’s engineering capabilities and her contributions to the machine industry were recognized when she was elected the first female member of the American Gear Manufacturing Association. She was also the first female member of the German Engineering Association and the first female elected a full member of the American Society of Mechanical Engineers.

In 2011, the ASME Foundation established the Kate Gleason Award, which recognizes the contributions of distinguished female leaders in the field of engineering.

The Kate Gleason College of Engineering at the Rochester Institute of Technology was the first engineering school named for a woman.

According to Dr. Hermann J. Stadtfeld, Gleason’s current vice president of bevel gear technology–R&D, 70 percent of the straight bevel gear machines installed in Europe can be traced to Kate’s sales activities and the “two-tool planers” she peddled at the turn of the 20th century.

“When we sell a straight bevel gear machine to one of those countries to replace an old straight bevel planer, I always think of Kate’s legacy,” Stadtfeld said.

Kate’s technical understanding of the gear cutting equipment she sold, along with her persistence and willingness to step outside the customs and conventions of the day, has earned her a special place in the history of cutting machine tools, alongside the invention of William Gleason’s original bevel gear planer.

For more information about Gleason Corp., visit www.gleason.com or call (585) 473-1000.

Bevel Gears: Then and Now

Bevel gears are cone-shaped and make it possible to transmit power at a 90° angle from the drive shaft of a car to its rear wheel axle. They are especially useful in differential drives, which allow two car axles to rotate at different speeds, as when a car rounds a corner.

According to Gleason Corp.’s Dr. Hermann J. Stadtfeld, all luxury sedans, SUVs and pickup trucks use one or two bevel gear sets. All semitrailers, jet engines and helicopters have multiple sets of bevel gears.

“Motor boats, ships and ocean liners, as well as train engines, use bevel gears,” he said. “Besides the bevel gears in jet engines, all airplanes use between 15 and 50 bevel gear sets for flap and rudder actuation.”

Stadtfeld has worked at Gleason since 1994. He and his team have obtained approximately 50 internationally filed patents on gear technology. Most of Gleason’s bevel gear processes and new kinds of gear forms have been developed during his time with the company.

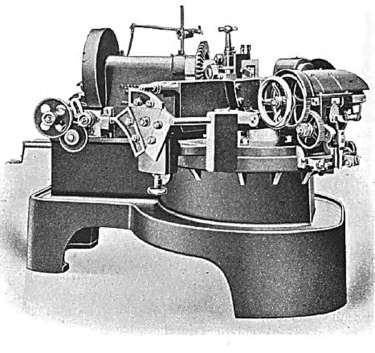

Gleason Works built this 24" bevel gear planer in 1907.

Because of their conical shape, bevel gears are more complicated to design and manufacture than standard cylindrical gears.

“It was more difficult to make bevel gears in William Gleason’s time because the theory of bevel gear generation is the most complex theory of all mechanical engineering disciplines,” Stadtfeld said. (William Gleason founded Gleason Works in 1865.)

“Design calculations were completed manually, which took days and weeks,” he said. “Due to the differences in precise calculations, many manufacturers used the trial-and-error method in order to iteratively improve the function of their bevel gears.”

By comparison, the most sophisticated design calculations today take only milliseconds of processing time with a computer.

Gleason’s first bevel gear planers were driven by rotation from a water wheel or steam engine and controlled by mechanical cams, linkages and gear trains, Stadtfeld said. In contrast, today’s machines are actuated by electric motors and controlled by a computer.

Stadtfeld explained that in the past, the tooth-forming process involved chip removal with two reciprocating cutting blades made from tool steel.

“Lots of oil was required to pour between the tool and chip-forming action in order to cool the process and prevent the tool from failing,” he said.

Today’s process involves application of rotating face cutters fitted with 30 to 50 blades made from coated carbide. The blade speed is 20 times faster than with earlier planers. Because of the many blades simultaneously involved and an advanced high-speed, dry-cutting process, productivity is more than 150 times higher in 2018 than in 1915, Stadtfeld said.

“We developed software and machines that take the difficulties of the past away from the bevel gear manufacturer so that now [the gears] are very easy to machine,” Stadtfeld said.

—H. Martin

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- lathe

lathe

Turning machine capable of sawing, milling, grinding, gear-cutting, drilling, reaming, boring, threading, facing, chamfering, grooving, knurling, spinning, parting, necking, taper-cutting, and cam- and eccentric-cutting, as well as step- and straight-turning. Comes in a variety of forms, ranging from manual to semiautomatic to fully automatic, with major types being engine lathes, turning and contouring lathes, turret lathes and numerical-control lathes. The engine lathe consists of a headstock and spindle, tailstock, bed, carriage (complete with apron) and cross slides. Features include gear- (speed) and feed-selector levers, toolpost, compound rest, lead screw and reversing lead screw, threading dial and rapid-traverse lever. Special lathe types include through-the-spindle, camshaft and crankshaft, brake drum and rotor, spinning and gun-barrel machines. Toolroom and bench lathes are used for precision work; the former for tool-and-die work and similar tasks, the latter for small workpieces (instruments, watches), normally without a power feed. Models are typically designated according to their “swing,” or the largest-diameter workpiece that can be rotated; bed length, or the distance between centers; and horsepower generated. See turning machine.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- planing machine ( planer)

planing machine ( planer)

Machines flat surfaces. Planers take a variety of forms: double-housing, open-side, convertible and adjustable open-side, double-cut and milling. Large multihead (milling, boring, drilling, etc.) planers and planer-type milling machines handle most planing work.