No automatic pallet changers on your machine tools? No problem if there’s a crane at the plant that doubles as an APC.

That’s the idea behind the Double Mast Crane-Automatic Pallet Changer, a multipallet loader from Fastems LLC in West Chester, Ohio. Capable of handling payloads up to 1,000 kg (2,205 lbs.), the DMC-APC can load machine tools directly and act as an APC.

The DMC-APC is designed for use in Fastems’ Flexible Manufacturing System. The company describes an FMS as a pallet-based automation system that incorporates machine tools chosen by a user. The goal is to feed machine tools with a rail-guided vehicle or robot to allow simultaneous setups and machining.

An FMS is made up of engineered modular components that fit into the factory of a user. These include a storage rack, material station, loading station, station command unit and stacker crane. The stacker crane features a load handler that moves pallets among storage, machines and the loading and material stations in the FMS.

When a stacker crane can accommodate only one pallet, the loader takes a finished part pallet from a machine tool and moves the pallet to the storage stacker, then picks up the next pallet of workpieces to be machined and delivers it to the machine tool. This scenario takes about 100 to 120 seconds, according to Fastems.

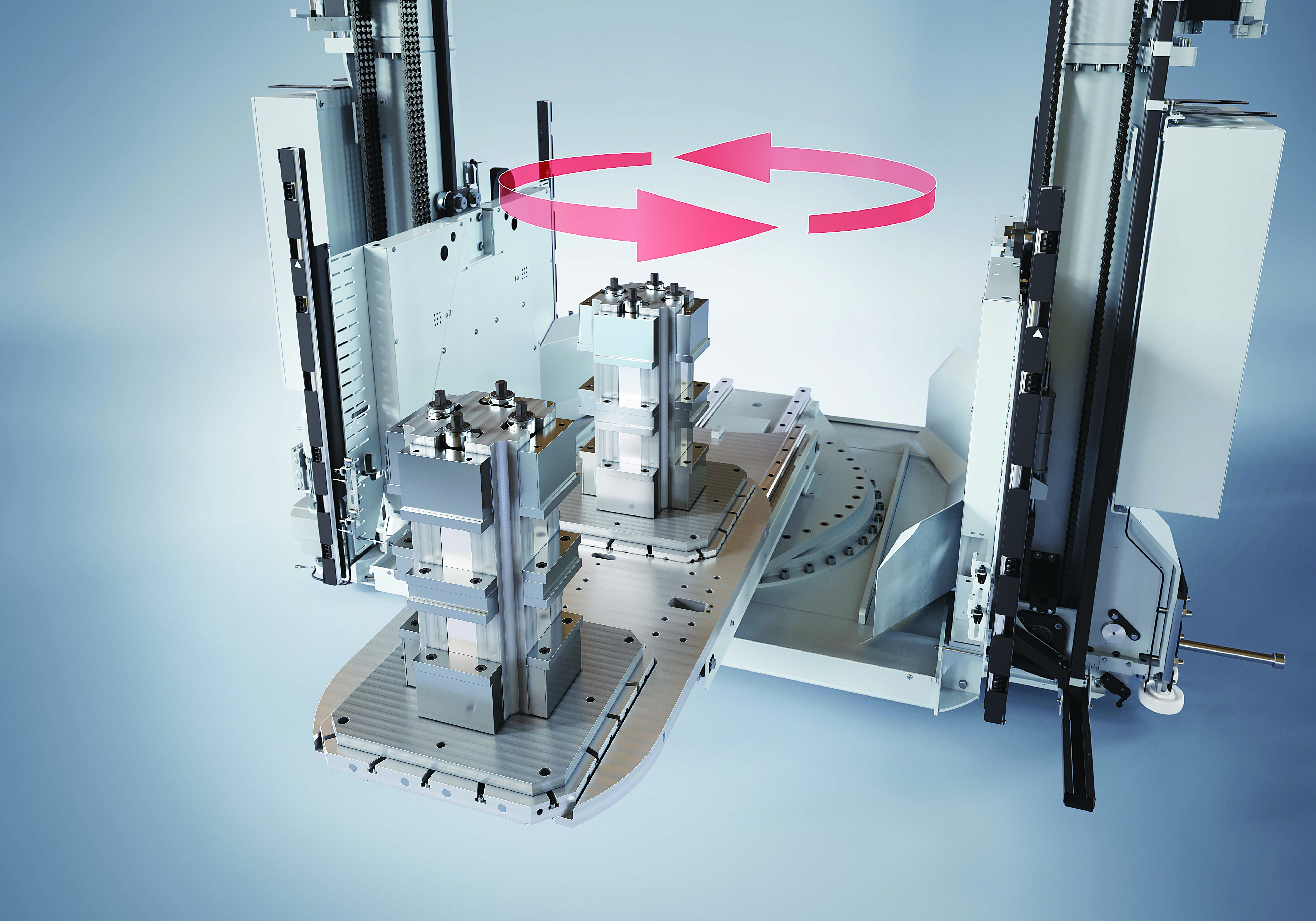

Unlike conventional stacker cranes, the DMC-APC can handle two pallets at a time instead of one, which allows the pallet-changing job to be done much faster than single-pallet loaders. Controlled by Fastems’ cell management software, the DMC-APC selects a workpiece-loaded pallet from the storage system and moves the pallet to a machine tool, where the DMC-APC picks up the finished part pallet, turns 180 degrees and places the pallet with the new workpieces into the machine tool. The company says this sequence of events takes about 30 to 40 seconds. By slashing pallet-changing time, Fastems notes, the DMC-APC can significantly boost machine tool utilization.

In addition, the company says FMS users employing the load handler on the DMC-APC don’t need to purchase APCs for machine tools, which can cost up to $100,000 each.

“Some machine tool builders build machines without a pallet changer,” said Central Regional Manager Chris Rezny. “So you could tell a builder to build you a machine without a pallet changer, and our system will do the pallet changing for you.”

Fastems also points out that the DMC-APC saves plant floor space because machines without APCs normally have smaller footprints than machines with APCs.

At present, the DMC-APC is limited in terms of the part sizes that it can handle.

“It’s basically meant for 500 mm (19.7") parts,” Rezny said. “That’s its sweet spot.”

However, he said part sizes ranging from 400 mm (15.7") to 500 mm should work with the system.

With its special capabilities, Rezny said the DMC-APC can give extra leverage to manufacturers in negotiations with machine tool builders. After adding an APC-less five-axis machine for finishing, for example, a manufacturer using an FMS and equipped with a DMC-APC can approach builders about supplying a four-axis machine without a pallet changer for roughing.

In this situation, he said, “You can ask, ‘What’s the credit for building a machine without a pallet changer?’ because you’re letting the system do the pallet changing.”

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flexible manufacturing system ( FMS)

flexible manufacturing system ( FMS)

Automated manufacturing system designed to machine a variety of similar parts. System is designed to minimize production changeover time. Computers link machine tools with the workhandling system and peripherals. Also associated with machine tools grouped in cells for efficient production. See cell manufacturing.

- flexible manufacturing system ( FMS)2

flexible manufacturing system ( FMS)

Automated manufacturing system designed to machine a variety of similar parts. System is designed to minimize production changeover time. Computers link machine tools with the workhandling system and peripherals. Also associated with machine tools grouped in cells for efficient production. See cell manufacturing.