An additive manufacturing process is helping machine shops create metal parts with complex internal cooling channels for dispensing liquids or gases layer by layer before final machining.

With additive manufacturing, end users can build a part from the ground up with 1mm- to 2mm-thick metal sheets. 3D modeling software is used to map out sophisticated internal passageways prior to CO2 laser cutting of each layer.

The key to the process is diffusion bonding, which essentially fuses the combined layers under a pressing force up to 4,000 kN and a temperature up to 1,400° C without the need of brazing or other filler material. Traditional machining then brings the exterior of the part to its final shape.

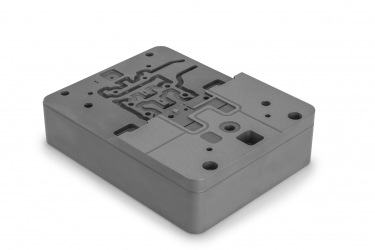

PVA TePla America offers additive manufacturing equipment that can create metal parts with complex internal cooling channels. Image courtesy of PVA TePla America

Using this technique, finished parts as large as 900mm × 1,250mm × 500mm can be constructed from stainless steel, titanium, zirconium, beryllium, aluminum, Inconel and tungsten. For machine shops serving the medical, aerospace, semiconductor or automotive industries, the technique provides a method to create parts that are difficult if not impossible to make using traditional CNC machines or less effective brazing or welding approaches.

Manufacturers like PVA TePla America Inc., Corona, California, offer multiple-cylinder systems with large pressing plates that can accommodate a variety of parts. By independently controlling each cylinder, PVA TePla America’s press provides extremely consistent pressure across the entire surface.

Besides selling the equipment, PVA TePla America creates diffusion-bonded parts using this technique through toll processing services offered by its parent company in Germany. Walt Roloson, R&D engineering manager at PVA TePla America, said an appealing aspect of the process is its ability to create the internal structures and join layers of dissimilar metals. In this regard, there is no restriction on materials because all tool steels are available in bulk sheets.

“Customers often come to us with requests to bond aluminum to molybdenum or stainless steel,” he said. “We are able to do that with diffusion bonding.”

The multilayer design also improves conformal cooling of plastic injection molds made in two-layer designs of tool steel and material like stainless steel.

“For the most efficient performance, conformal cooling channels should be adapted as precisely as possible to the outer shape of the mold,” Roloson said. “The higher the number of layers bonded together, the more precisely it can match the outer shape.”

By improving cooling performance, melted resins can be injected at higher pressures to improve cycle times as much as 40 percent while enhancing product quality.

Once the layers are joined by diffusion bonding, Roloson said traditional machining techniques can create the final external shape.

“Due to the molecular bonding of the layers, the final part often shows no interface lines or striations,” he said. “The interface of one material is actually blended into the other one and vice versa, even with dissimilar materials.”

Contact PVA TePla America at 800-527-5667, or visit www.pvateplaamerica.com.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- diffusion

diffusion

1. Spreading of a constituent in a gas, liquid or solid, tending to make the composition of all parts uniform. 2. Spontaneous movement of atoms or molecules to new sites within a material.

- tool steels

tool steels

Group of alloy steels which, after proper heat treatment, provide the combination of properties required for cutting tool and die applications. The American Iron and Steel Institute divides tool steels into six major categories: water hardening, shock resisting, cold work, hot work, special purpose and high speed.