On March 2, mHUB, a physical-product innovation center and microfactory, celebrated its official grand opening in Chicago. The center is designed to galvanize the area’s manufacturing ecosystem by generating innovative ideas, attracting world-class talent and fostering collaboration.

To date, mHUB (the “m” stands for numerous concepts, including manufacturing, make, machines, Midwest, mentor and markets) has attracted more than $8 million in partner funding, with a variety of sponsors. These include Autodesk and founding-partner GE. The center offers Chicago manufacturers access to state-of-the-art equipment and resources to develop and bring new products to market. The 63,000-sq.-ft. facility, formerly home to the Milwaukee Iron and Metal Co., contains 10 fabrication labs, including electronics, plastic fabrication, metals, textiles and rapid prototyping.

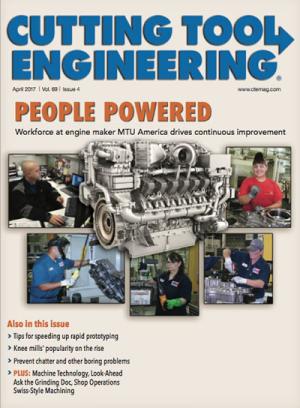

Maxwell Emcays, an mHUB member, uses a laser cutter at Chicago’s product innovation center to cut wood for one of his art projects. Image courtesy of mHUB.

The center is working in partnership with the Technology & Manufacturing Association to add large, production CNC machine tools and to provide National Institute for Metalworking Skills Machining Level I and II certification on-site. There are plans to add plastic injection moldmaking equipment this year, according to Haven Allen, executive director of mHUB.

MHUB has more than 100 members, representing around 35 companies, in a roughly 7:3 entrepreneur-to-established-manufacturer ratio, as well as a handful of service providers. Allen said the goal for 2017 is to grow to 250 members, adding that the center can accommodate about 1,000 members.

In conjunction with the grand opening, GE announced the opening of the first regional GE Fuse location on-site. GE Fuse is a new approach to manufacturing that reportedly accelerates product and technology development by combining open innovation with small-batch manufacturing.

In addition to producing products, manufacturing involves taking care of business.

At mHUB, Delna Sepoy tries the Keyo palm-scanner payment terminal. Image courtesy of mHUB.

Allen said, “mHUB is here to create new jobs and to create new manufacturing companies, and we are working with our regional manufacturing base to make sure that what is invented here is manufactured locally. Having manufacturers engaged in the innovation process and helping product developers think about how a product is actually manufactured” serves that mission.

According to Allen, mHUB was conceived by World Business Chicago, an economic development firm that focuses on regional growth, job creation and workforce development. Other WBC initiatives include apprenticeship programs, a new community college training center and the 1000 Jobs program, which has placed over 1,000 nonmanufacturing people into manufacturing jobs.

“There’s a strong sense that we have to create new businesses and new products—not just wait for companies to come here—in order to really grow the manufacturing industry,” Allen said.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.