The common sources of machining information all make assumptions that users must be aware of before they implement the recommendations.

Apart from personal experience, the three most common sources of information for designing machining processes are commercial databases, tooling vendors, and corporate databases. These sources differ in the types of data they offer the user (Table 1).

Commercial databases are published in manuals, in handbooks, or in electronic form. They present generic data concerning the correct speed, feed, and depth of cut (DOC) when using a class of tools for a specific operation on a family of materials. (For example, the database may offer machining data for the single-point turning of medium-carbon steels with coated carbide.) Vendors typically base their data on a specific tool and its use with a family of workpiece materials. Machinability data are based on specific tool and workpiece-material conditions. Corporate data (collected from actual applications) represent empirical data drawn from observations of the specific tool and workpiece material involved. The data provide information about the effects a particular machine will have on the operation or the influence workpiece-material characteristics such as its composition, heat-treatment, stiffness, and surface finish will have on the end results.

The most common commercial source for machining data is the Machining Data Handbook. The handbook was originally published by Metcut Research Associates, Cincinnati. The publication was based on a 260-page pamphlet Metcut produced under contract to the U.S. Ordnance Corps. The pamphlet contained speed, feed, and fluid recommendations for 30 cutting and grinding operations, as well as a section on tool geometry and the economics of machining. With funds from the U.S. Defense Department, Metcut published three editions of the Machining Data Handbook in an effort to improve machining practices in the governmental and commercial sectors. In 1990, Metcut closed its Machinability Data Center, and the Institute of Advanced Manufacturing Sciences (IAMS), Cincinnati, took responsibility for publishing the handbook and updating the data.

The current edition of the handbook is the third edition. It contains more than 1300 pages of recommendations for 35 cutting and grinding operations, plus nearly 1000 pages of technical information about tools, fluids, materials, and the quality of the machined surfaces. The basic machining data are also available as software for Windows-based PCs. The software, called CUTDATA, currently offers about 30% more data than the most recent edition of the handbook. The database has more than 600 workpiece-material groups covering most engineering materials, including ferrous, nonferrous, high-temperature, refractory, and nonmetallic materials. IAMS updates this information about twice a year.

Vendors are an equally important source of information. A survey conducted by IAMS indicates that end users primarily depend on their cutting tool suppliers for machining information and recommendations. Traditionally, the sales contact—backed by the expertise of those in the vendor’s laboratory—passed this information on to his or her customers. Vendors then began to publish speed and feed recommendations in their catalogs. Now, most vendors supply their customers with computerized databases containing this information. Many of these databases are free. Some vendors include the information in electronic form as part of their CD-ROM catalogs.

Machining information supplied by tooling vendors is much more tool-specific than that currently provided by commercial databases. The information will probably cover fewer workpiece-material categories, however. The selection process for many of these vendor-supplied packages is tooling driven. The customer selects a new grade based on the specifics of an existing application and an analysis of the application’s performance requirements or the current tool’s failure mode.

Table 1: The three sources of data and the information they represent.

In most instances, the vendors’ data will be the best source of information about current developments in tools and coatings. And users will find the databases especially useful for comparing tool-material grades, coatings, and edge geometries. This type of data is most suitable for users who want to optimize their tooling for a specific operation. Typically, it is the medium- to high-volume applications that offer the opportunity for such optimization. For a company that stocks just a few general grades of tools for a variety of workpieces, a database based on workpiece-material specifications is more appropriate.

Machinability evaluations are another form of specific machining data. Typically, these data consist of recommended speeds, feeds, and DOCs to achieve a specified life for a certain tool material. A more comprehensive guide might include detailed information about the machine, tooling, work material, and test conditions under which the data were developed, and it would list tool life for a variety of operating conditions. The source of this information may be a tooling or material vendor, in-house records, or a third party contracted to research a specific operation. The key distinction between machinability evaluations and a vendor’s tooling data is that machinability evaluations are based on the material to be machined as well as the tools used to machine it. The specific operation and metalworking fluid may also be used for testing to arrive at these recommendations. If a tool-life curve is associated with this data, then the user can predict the impact a change in operating parameters will have on tool life and can perform an economic analysis of the application.

A user is justified in testing a specific application to evaluate machinability only if it is a high-volume application or if the workpiece is extremely valuable. Users may be able to find pre-existing data, however, generated by researchers, tooling vendors, material suppliers, or other users with similar applications and published in commercial databases or vendor literature.

The data that will be the most relevant to an application are data that have been generated from observations of an actual production application of the same type. Typically, these empirical data are generated in-house. Shops can use this data to set up new parts that are similar to those currently in production. This is the key concept behind the use of group technology in computer-aided process-planning (CAPP) systems. These systems organize and process all the information (such as resource capabilities and costs, process times, work instructions, and bills of material) needed to produce a product. Under the concept of group technology, these systems group similar components into categories and apply the same machining data to all components in each category.

Data collected while machining real parts include the effects that the tool and workpiece have on the operation, as well as performance data that can be attributed to the use of coolant, the stiffness and accuracy of the machine tool, the stiffness of the workpiece, and local thermal conditions. Data from the shop floor will, over time, reflect changes to correct suboptimal shop practices. Speeds and feeds will be reduced until the process performs to an acceptable level of reliability. The ultimate parameters used may reflect the actual capability of the tool, or they may reflect cultural factors such as operator training or the shop’s purchasing practices.

But there is also the danger that suboptimal practices will be promulgated if users rely exclusively on shop-floor data. Inefficient ways of machining parts may become entrenched if machinists choose a certain setup simply because it’s the way the shop has always machined the part. To remain open to improvements, most shops use a combination of commercial, vendor, and empirical data. This balances a shop’s need to be technologically up-to-date with the need for timely production schedules. Some shops find it useful to combine external and internal information into a single database. Many of the commercial and vendor databases allow users to combine data generated within the company with the database’s recommendations.

Machining Data’s Limitations

Before using any of this data to design a manufacturing process, users should be aware of the number of assumptions that are implicit in most machining data, because these assumptions limit how accurately the data will apply to any given application. This is not to say that the data cannot be used to design processes, only that the process designer must be ready to compensate for these limitations.

Many users of machining data do not understand how the data they use was generated or how the source of the data relates to its use with the operation they are designing. Because the data tends to be conservative, misapplication of the data seldom leads to catastrophic failure. But users often assume that speed and feed recommendations are maximums that should not be exceeded. As a result, they design processes around these recommendations that do not yield competitive levels of productivity.

Machining data are usually presented as a recommended speed and feed to machine a range of DOCs in a given workpiece material. The tool life that will result from these parameters is generally not noted. For example, the Machining Data Handbook lists only broad tool-life ranges that are applied to all of the handbook’s speed and feed recommendations. The data in the handbook are intended to yield a tool life of one to two hours for HSS tools. The more aggressive speeds and feeds listed in the handbook for indexable carbide tools will yield about 30 to 60 min. of tool life. Target life for ceramic tools is lower, and that for superabrasive tools may be much higher.

Such data are not intended to provide an accurate estimate of the longest tool life possible, but rather a successful set of initial machining parameters. After making and analyzing a trial cut, users often find they can increase speeds and/or feeds to achieve higher material-removal rates (mrr) and still obtain a tool life that meets the requirements of the shop and the application.

There is a common misconception among users that those who publish machining data perform machinability tests on each specific material to obtain their information. In fact, the data derived from specific machinability tests performed in-house or by an independent laboratory accounts for a relatively small percentage of the available data. The time and expense of running statistically significant tool-life tests on all the possible combinations of tools and workpiece materials are prohibitive. Instead, much of the data represent a combination of laboratory test results and a compilation of industry practices. To generate this composite-type data, the data publishers collect several data points averaged from a number of applications for which data is available. These individual data points are combined to approximate a tool-life curve, from which the recommended parameters are derived.

Databases of machining parameters also do not offer parameters for every heat-treatment condition available for every material. Materials that share machinability characteristics are grouped together in classes to keep the database to a reasonable size. The Machining Data Handbook has 61 primary material groups, each of which is further divided by composition and heat-treatment condition into as many as 46 subgroups of materials with similar machinability characteristics. For instance, the handbook lists seven alloys that exhibit common characteristics when turned under a subdivision of the stainless-steel primary material group that includes all free-machining, wrought, martensitic materials in the 275 to 325 Bhn range. Vendor databases also use workpiece-material grouping to make the amount of data more manageable.

The larger the number of materials within a “machinability group,” the lower the chances that a user will find the recommended operating parameters for the group to be the optimum for his or her particular application. However, grouping workpiece materials is the most reasonable approach, because the alternative—listing data to reflect every factor that can affect performance—would be too expensive and cumbersome.

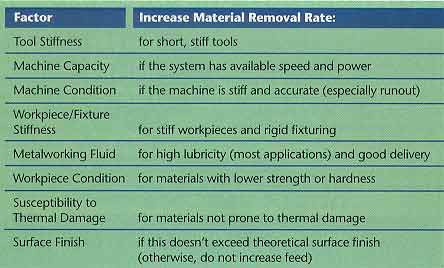

Because most machining data are not generated for a specific application, a recommendation should serve as a starting point. Users should modify these parameters during runoff to optimize the application. (The exception to this is where quality-driven process-control standards are in place that prohibit increasing the mmr beyond a specified range.) For most operations based on generic data, the user can increase the mrr over the recommended parameters. See Table 2 for the key factors that will determine if the mrr can be increased.

In some cases, however, the user may want to use a lower mrr than the recommended rate. Key factors that might lead a user to decrease the recommended mrr are the precision or value of the workpiece or the risk to the operation that a catastrophic tool failure might pose. For high-precision components, it may be necessary for the user to reduce cutting forces by reducing the feed per tooth or DOC to produce the necessary surface finish or reduce the parameters to allow a single tool to make the entire cut and thereby avoid stoppages that might mar the finish. Users also may choose to machine high-value components less aggressively to avoid the high cost of scrapping or reworking the part. Similarly, a user may run an operation conservatively to extend tool life, thereby reducing the number of tool changes when tool replacements are difficult or time-consuming.

For some operations, the user may want to go beyond the available machining data and calculate the machining parameters that will produce the minimal total operating cost. To do this, the user will have to use a full tool-life curve to calculate the impact that a change in the mrr will have on tool life. This information is combined with the burden rate for the process and the tool-change penalty cost to derive the conditions that will result in the lowest cost.

Few users actually run their operations under minimal-cost conditions, however. This may be because some other process paces the flow of workpieces through the system. It may be that the user doesn’t believe it is worth the effort to collect the data and do the calculations. If it is not necessary to strive for minimal cost, the user generally does not have to calculate a tool-life curve. Instead, the operator will empirically adjust the operating parameters to meet the key production requirements.

When making changes to their machining data and the format in which the information is delivered, data publishers consider the users’ ability to interpret this data. Historically, users of machining data have been process engineers or operators who could use their experience with the process to adapt the recommendations for their specific needs. Unfortunately, the level of practical machining experience is rapidly diminishing among users throughout the manufacturing community. As a result, machining data must become more detailed, more robust, and more explicit about the assumptions made and the limitations of the data’s applicability.

Another important factor to which data publishers must respond is the rapid development of the communication infrastructure. We are witnessing radical changes in the way data are communicated, the nature of the data, and sources of information. This is leading to more powerful and diverse tools for handling data and to new business relationships based on shared information.

Table 2: Factors that may allow users to machine with more aggressive parameters than the recommended parameters.

Alternative Sources

As all of these changes influence the creation and dissemination of machining information, a number of data sources are emerging to supplement the information supplied by more traditional sources. Among these niche sources are material suppliers, which use machining data as development and marketing tools. Such data tend to focus on newly developed materials of two primary types.

The first type of materials is designed specifically to be more easily machined. These tend to be new varieties of common materials such as steel, aluminum, and brass alloys. An example of such a material is dispersion-strengthened powder-metallurgy copper alloy, which was introduced at a materials conference along with machining data in a computerized format. Small improvements in the machinability of these materials are significant, because the materials are so widely used. For these materials, machinability is an order-winning criterion.

The second type of materials is composed of high-performance materials such as high-temperature and high-strength alloys and composites. These materials are sold on their outstanding performance characteristics, but potential buyers also must be provided with information on how to machine them. In this case, machining data from the materials supplier are an order qualifier. An example of how machining data could be used in this way could be seen with the introduction of aluminum-silicon-carbon metal-matrix composite materials. The producers of these abrasive materials sponsored a number of machinability projects to determine the most cost-effective methods of machining them. Their studies included comparisons of polycrystalline-diamond and diamond-coated tools for turning, milling, and drilling.

In both cases, the material suppliers developed machining data and supplied it to customers along with the material. This type of data typically is quite specific with respect to the workpiece material, and more general concerning the tool recommendations.

Machining databases have been common in CAPP systems for many years. More recently, developers of CAD/CAM systems have been including them in their products as well. Currently, these databases are used by CAM process designers to select speeds and feeds as NC code is developed. Eventually, the systems will incorporate enough data on the process, the machine, the tooling, and the shop’s costs to allow design engineers to see what a just-designed part will cost to manufacture. With this information, engineers can evaluate different designs and processes and select the most economical one.

As this information becomes widely available, it becomes increasingly important for users to understand the origins and limitations of the engineering data that is at their disposal. Future systems may have the ability to judge the applicability of the data on their own and make the necessary adjustments to adapt data from one application for use on another. Process modeling, rules-based expert systems, and artificial intelligence systems are available or under development to improve the robustness of the data in this way by factoring in additional process information.

As sub-tier suppliers improve their information infrastructure, the intercompany exchange of machining data becomes more practical. In one example, a large manufacturer has created an Internet-accessible machining database for its suppliers. This company uses a wide variety of materials, many of which are uncommon or proprietary, and has done extensive machinability testing and process development over many years. As the company subcontracted more of its machining, it became important to make the company’s machining expertise available to the supplier base. By sharing this information, the manufacturer could ensure that its subcontractors were aware of best practices. The mechanism used to disseminate this information is a password-protected Internet home page where suppliers can access corporate machining data. While the database used internally and externally is the same, for security reasons, this database is completely separate from the manufacturer’s other information systems.

A second example is a major manufacturer that is implementing a cost-estimating system that includes machining databases to verify quotes from suppliers. The next step will be for the customer and its suppliers to move to a common software platform, based on a common machining database. It is important to note that this system would not preclude a supplier from gaining a competitive advantage by developing techniques to machine at higher removal rates than those recommended by the database.

A final example comes from the university environment, where the Machine Tool Agile Manufacturing Research Institute (MTAMRI) uses CUTDATA as a basic data source for machining process models that predict forces and workpiece-material behavior but not tool life. MTAMRI is actually a consortium of nine universities. The process models reside at the various sites and are seamlessly connected over the Internet as the users access each module.

A key advantage of each of these systems is that the data are maintained in a single location. Therefore, any updates are simultaneously and immediately available to all users.

Data Development and Exchange

As machining data become more widely shared, and as the user base becomes more diverse, the data must also become more robust. The data’s user must know the assumptions and local conditions associated with a piece of information when the data are being used by others with a variety of backgrounds at different sites. The data must also be presented in a consistent format to allow a number of disparate users to share information.

For a number of years, the ISO/TC 29/TG task group of the International Organization for Standardization (ISO) has discussed the need to formalize the standards for the exchange of computerized machinability data. The scope of the preliminary discussions covered the transmission of data, including tooling geometry, workpiece and tool attributes, machining conditions, experimental data, and application data. Based on these discussions, ISO formed the ISO/TC 29/WG 34 work group, which is a body officially sanctioned to create a standard. The American National Standards Institute (ANSI) became involved with the ISO workgroup and will sponsor activity on this issue.

About the Author

John Pfeiffer is program development manager for the Institute of Advanced Manufacturing Sciences Machining Xcellence Inc., Cincinnati.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- computer-aided manufacturing ( CAM)

computer-aided manufacturing ( CAM)

Use of computers to control machining and manufacturing processes.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- high-speed steels ( HSS)

high-speed steels ( HSS)

Available in two major types: tungsten high-speed steels (designated by letter T having tungsten as the principal alloying element) and molybdenum high-speed steels (designated by letter M having molybdenum as the principal alloying element). The type T high-speed steels containing cobalt have higher wear resistance and greater red (hot) hardness, withstanding cutting temperature up to 1,100º F (590º C). The type T steels are used to fabricate metalcutting tools (milling cutters, drills, reamers and taps), woodworking tools, various types of punches and dies, ball and roller bearings. The type M steels are used for cutting tools and various types of dies.

- machinability

machinability

The relative ease of machining metals and alloys.

- medium-carbon steels

medium-carbon steels

Group of carbon steels designated by American Iron and Steel Institute numerical classification as AISI 1029, 1030, 1034, etc., up to AISI 1053, for a total of 16 grades. They are often selected where higher strength is required. Most commonly used steels for machined components. Composition of medium-carbon steels is: 0.25 to 0.55 percent carbon, 0.30 to 1.00 percent manganese, 0.040 percent (maximum) phosphorus and 0.050 percent (maximum) sulfur. See high-carbon steels; low-carbon steels.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- numerical control ( NC)

numerical control ( NC)

Any controlled equipment that allows an operator to program its movement by entering a series of coded numbers and symbols. See CNC, computer numerical control; DNC, direct numerical control.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- superabrasive tools

superabrasive tools

Abrasive tools made from diamond or cubic boron nitride, the hardest materials known. See CBN, cubic boron nitride; diamond; PCD, polycrystalline diamond; single-crystal diamond.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.