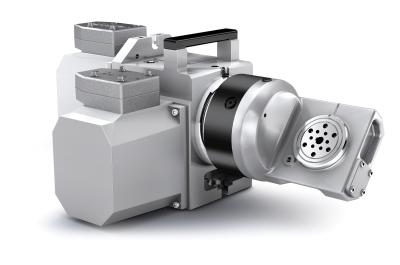

The TRT70 dual-axis rotary table from Haas Automation delivers high-speed and accurate positioning for 3+2 and full 5-axis machining of small, complex parts – like those found in the medical, dental, and jewelry industries. The unit’s ultracompact size and light weight reportedly make the TRT70 the perfect dual-axis solution for even the smallest machining center.

The TRT70 uses powerful brushless servomotors to provide 60 ft-lb (81.3 Nm) of torque on the tilt axis and 40 ft-lb (54.2 Nm) on the rotary axis; indexing speeds of 410 deg/sec on the tilt axis and 620 deg/sec on the rotary axis ensure short cycle times. The unit provides ±120 degrees of tilt and 360 degrees of rotation to position parts to almost any angle for machining. The precision-ground 70 mm (2.76") platter features multiple bolt patterns and a precision through-bore for versatile fixturing, and will swing parts up to 4.0" (102 mm) diameter. The maximum platter capacity is 3 lb (1.4 kg).

At just 18.5" (470 mm) wide and 10" (254 mm) deep, the TRT70 easily fits into even the smallest machining center, or can be mounted on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises. It is the perfect complement for Haas Automation’s new CM-1 Compact Mill or existing OM-Series Office Mills. Like all Haas rotary tables, the TRT70 can easily be removed when not needed.

Contact Details

Related Glossary Terms

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.