TRANSOR+PLUS Magnetic Separator

TRANSOR+PLUS Magnetic Separator

Transor Filter USA's TRANSOR+PLUS expands the high performance capabilities Transor is known for by including a built-in rare earth magnetic separator into its compact design.

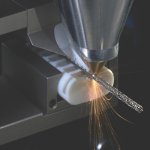

Transor Filter USA's TRANSOR+PLUS expands the high performance capabilities Transor is known for by including a built-in rare earth magnetic separator into its compact design. Rare earth magnets can be up to 4 times stronger than standard magnetic separators and do an excellent job of acting as a pre-filter for applications involving tool steel, HHS or other magnetic materials.

In normal operation, dirty oil flows from the machine back to the TRANSOR+PLUS and then passes over the magnetic separator before draining into the dirty oil storage area of the filter. Oil is then filtered to Oneµm and chilled before being delivered to the machine upon request. TRANSOR+PLUS is offered in a number of different sizes with flow rates starting at 30 gpm and expanding in 30 gpm increments. As Transor elements are automatically cleaned rather than replaced, maintenance on the system is very low. As an additional hands-off feature, an automated sludge handling device is available that deposits dirt removed during backflushing into a 55 gallon drum for easy disposal or reclamation.

Transor Filter has long been on the forefront of this issue by offering Oneµm filtered oil and temperature control to a level of +/-0.1°C. Companies all over the world have employed this technology in the manufacturing of carbide cutting tools. The benefits have been so significant that users have looked for other applications that involve tool steel, HHS or other materials that could benefit from incorporating a Transor into their process.