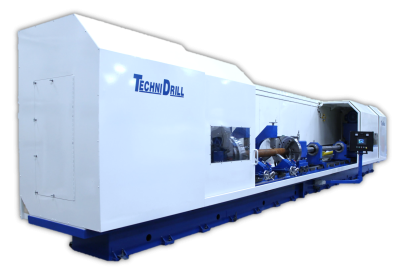

The TechniDrill TBTA-10-180 is a deep-hole drilling machine using the BTA process (Boring & Trepanning Association). It can drill holes up to 10 inches in diameter from solid using the trepanning process. The machine has applications is both the aerospace and oil & gas industries.

The trepanning process doesn’t drill the entire diameter of the hole, only a ring of material on the periphery. Instead of turning all the removed material into chips, a core is left in the center of the hole. This enables the machine to drill larger diameter holes with less required horsepower.

The TBTA-10-180 is a single spindle machine with 10 inches (254 mm) of trepanning diameter capacity and 180 inches (4,572 mm) of trepanning depth. It has the capability for both a rotating tool and a counter-rotating workpiece, both of which are driven by 100 HP motors.

Contact Details

Related Glossary Terms

- drilling machine ( drill press)

drilling machine ( drill press)

Machine designed to rotate end-cutting tools. Can also be used for reaming, tapping, countersinking, counterboring, spotfacing and boring.

- trepanning

trepanning

Drilling deep holes that are too large to be drilled by high-pressure coolant drills or gundrills. Trepanning generates a solid core and normally requires a big, powerful machine. Shallow trepanning operations can be performed on modified engine or turret lathes or on boring machines. See boring; drilling; spade drilling.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.