Allied Machine and Engineering proudly announces their revolutionary high-penetration drilling system, the T-A Pro. After 35 years of spade drilling success with their iconic T-A (Throw Away) insert, the best just got better. Allied Machine’s team of engineers developed technology that takes THE "go-to" solution for general purpose holemaking to a performance level previously unachievable by a spade insert.

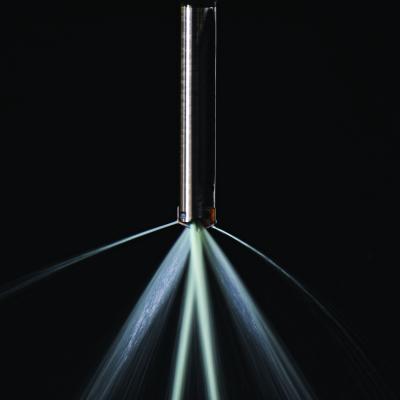

The T-A Pro drill combines material-specific insert geometries, a redesigned drill body and a proprietary coolant-through system to allow penetration rates which run at speeds nearly 30% faster than other high performance drills on the market. Coolant outlets are designed to direct maximum flow to the cutting edge providing quick heat extraction where it is most critical - even at significantly higher speeds. Material-specific insert geometries produce impeccable chip formation and the drill body incorporates straight flutes redesigned for maximum coolant flow and excellent rigidity. These design elements combine to extend tool life, create consistent quality holes, and provide superior chip evacuation. As a result, the T-A Pro drill offers machine shops and high production manufacturers a spade drill with incredible speed and a cost per hole averaging 25% less than existing drills.

The T-A Pro drilling system will be available in diameters ranging from 0.4370” – 1.882” (11.1mm – 47.80mm) and is ideal for holes ranging in stub, 3xD, 5xD, 7xD, 10xD, 12xD, and 15xD depths. The drill will be stocked in both imperial and metric shanks, with flat and cylindrical variants. The carbide insert geometries offered initially will cater to the following ISO material classes:

- Steel (P) with AM300 coating

- Cast iron (K), with TiAlN coating

- Non-ferrous (N) with TiCN coating

Product manager, Sal Deluca, states, “The T-A Pro drill is designed for use in applications ranging well beyond general purpose drilling. It truly will target all industries, offering phenomenal tool life at high penetration rates, especially in situations where the balance of chip formation at high penetration is critical.”

The T-A Pro drilling system will be available to order from Allied Machine’s distributor partners in October 2020.

Contact Details

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- spade drill

spade drill

Flat end-cutting tool used to produce holes ranging from about 1" to 6" in diameter. Spade drills consist of an interchangeable cutting blade and a toolholder that has a slot into which the blade fits. In horizontal applications, universal spade drills can achieve extreme depth-to-diameter ratios, but, in vertical applications, the tools are limited by poor chip evacuation.

- spade drilling

spade drilling

Drilling operation in which a machine powers a cutting tool consisting of a holder and flat, interchangeable end-cutting blades. Spade drilling takes over where twist drilling leaves off; requires more power and a larger machine but offers lower cost and greater rigidity. Large-diameter spade drills are used when trepanning is impractical or impossible. See drilling; trepanning.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- titanium carbonitride ( TiCN)

titanium carbonitride ( TiCN)

Often used as a tool coating. See coated tools.