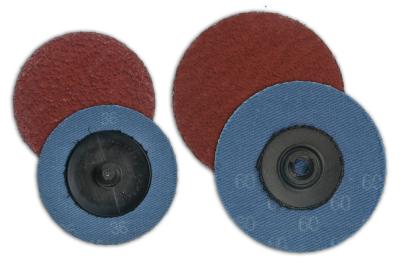

Weldcote offers its new lines of Quick-Change, Roll-On and Turn-On ceramic C-Prime discs for steel, stainless steel, ferrous and nonferrous metals.

Used for finishing, grinding, deburring and blending applications, Weldcote’s high-quality Quick-Change, Roll-On, ceramic C-Prime discs are manufactured of an improved ceramic grain structure that is available in seven grits ranging from 24 to 120 in its 2-inch size disc and six grits ranging from 24 to 120 in its 3-inch size disc. Its Quick-Change, Turn-On, ceramic C-Prime discs are available in six grits ranging from 36 to 120 in its 2-inch size disc and three grits ranging from 36 to 80 in its 3-inch size disc.

Using an improved manufacturing technology, Weldcote has developed a proprietary ceramic abrasive grain with a finer crystallized structure that offers longer life, more aggressive grains and improved self-sharpening features when compared to traditional ceramic products. The ceramic grain improvements provide high metal-removal rates at fast cutting speeds with low grinding temperatures and low friction.

“Our new Quick-Change ceramic discs provide users with longer life and a higher rate of material removal,” said Joe O’Mera, CEO of Weldcote. “The coated discs, which can be quickly and conveniently changed out, are constructed entirely in the U.S. with a proprietary new material that provides more aggressive performance.”

The new Weldcote Quick-Change, Coated, Roll-On and Turn-On ceramic discs eliminate the need for installation tools due to their twist-on-and-off attaching systems, which allows for rapid disc change and maximizes productivity by minimizing downtime.

The line is entirely made in the U.S., from design and lamination, to its die-cut and spin-weld processes.

Contact Details

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.