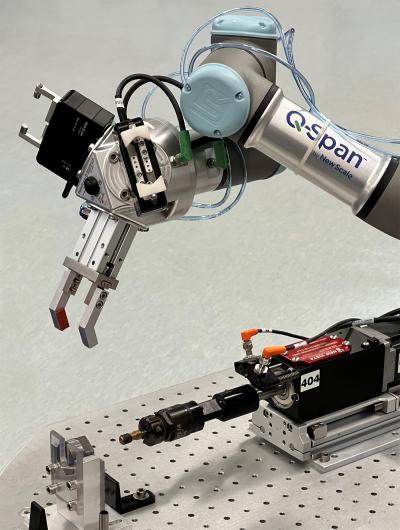

Thread verification is the latest enhancement to New Scale Robotics’ Q-Span® Automated Gauging System, a do-it-yourself (DIY) robotic automation system for quality teams in high-mix, small-batch manufacturing. The Q-Span Gauging System automates gauging processes by combining existing manual gauges with a collaborative robot, grippers for part handling, easy-to-use metrology and robot control software, and automated data collection.

The robot arm loads parts into a fixture and activates the thread gauge to verify or chase threaded holes or external threads. The Q-Span System can then sort parts based on measured data, such as thread depth of blind holes, or reject parts for defects such as missing, short, or improperly formed threads. Systems can be configured for “GO” gaging, “NO GO” gaging, combination gaging, or even thread chasing.

Data from all gauges in the Q-Span System – including thread gauges, robotic calipers, LVDT probes, drop gauges, bore gauges, laser micrometers, vision system, 2D telecentric profilers, and more – is combined into one convenient output for statistical process control (SPC). Data from any or all gauges can be used in real time for in-process decision making and process monitoring.

The Q-Span Gauging System incorporates a Universal Robots (UR) collaborative robot for flexibility, ease of use, and rapid return on investment. The mobile workstation table fits into existing workspaces and work flows. New Scale Robotics incorporates gauges and grippers to meet each customer’s initial needs, and users can easily configure the control software themselves for additional parts and processes. No robotics experience or special training is needed.

Contact Details

Related Glossary Terms

- fixture

fixture

Device, often made in-house, that holds a specific workpiece. See jig; modular fixturing.

- metrology

metrology

Science of measurement; the principles on which precision machining, quality control and inspection are based. See precision machining, measurement.

- process control

process control

Method of monitoring a process. Relates to electronic hardware and instrumentation used in automated process control. See in-process gaging, inspection; SPC, statistical process control.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.

- statistical process control ( SPC)

statistical process control ( SPC)

Statistical techniques to measure and analyze the extent to which a process deviates from a set standard.

- vision system

vision system

System in which information is extracted from visual sensors to allow machines to react to changes in the manufacturing process.