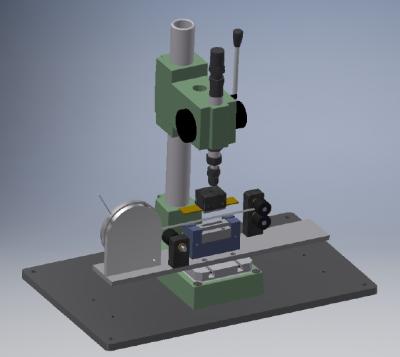

Leading Marks LLC announces a package for pattern labeling that improves legibility for cast-in identification, and provides cost savings through labor and material costs. A marking press and a custom designed accessory package impact legends in one stroke of the press rather than rotating wheels one character at a time.

The core of the package that hammers in the legends is a spring-loaded impact press. These units are proven marking devices with low-maintenance requirements. While manual systems are most common for replacing traditional pattern labeling devices with single character wheels, semi-automated systems are available for high-volume labeling requirements.

A steel-type arrangement embosses the characters into foil tape. The male type is mounted in a steel chase, nested on a manual feed assembly. Included in the feed assembly is a spool feed for the material, friction rollers, and a manual knob for advancing the material. Automated systems included more advanced material feed arrangement.

Three standard chases accommodate a range of character sizes. Chase assemblies can be interchanged to accommodate a wider range of sizes and tape guide arrangements. Character sizes range from 1/8” up to 3/4" high. Standard alphanumeric characters, as well as symbols and logo are available and quoted upon request.

The accessory package is designed to accommodate three standard tape widths; 13/32”, 5/8” and 7/8”. The 5-mil aluminum tape comes with rugged adhesive that is more pliable on curved surfaces than plastic tapes common to the pattern labeling process.

Contact Details

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.