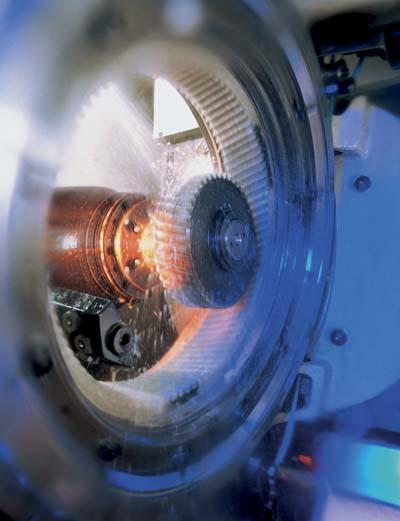

Gleason Corp. has introduced a new series of Opti-Form Honing Wheels that reduce the time typically required to perform the initial tool dressing by as much as 50 percent, while at the same time improving both the tool life of the honing wheel and the master gear used for dressing.

Conventional honing wheels generally require a slow, tedious initial dressing process to finish form the wheel with the required gear tooth characteristics. This can take as long as 45 minutes to complete, during which the honing machine is not producing parts. But by using the new Gleason Honing Wheels, end users can eliminate as much as 50 percent of this time, since the wheels arrive with critical features like profile, lead crowning and low run-out already produced in advance using an exclusive process developed by Gleason-HURTH. As a result, the wheel requires only a minimal amount of dressing and stock removal before it's ready to go into production. The end result is a honing wheel that is much faster to condition and inherently more accurate, and with an increase in useable diameter and corresponding tool life. In addition, the diamond-plated dressing gear experiences less wear per initial dressing, increasing its tool life as well. Gleason's series of Opti-Form Honing Wheels are designed for versatility as well. Outside diameters range from 270mm to 400mm, widths up 60mm, modules from 0.8 to 5mm, and with a variety of materials to choose from to meet the requirements of a wide range of applications, and use on most modern Gleason and non-Gleason machines.

Contact Details

Related Glossary Terms

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.