Onboard Reference System

Onboard Reference System

Prophesee SA (formerly Chronocam) introduced its first commercial implementation of the company's event-based vision technology for machines. The Onboard reference system is aimed at developers of vision-enabled industrial automation systems such as robots, inspection equipment and monitoring and surveillance devices.

Prophesee SA (formerly Chronocam) introduced its first commercial implementation of the company's event-based vision technology for machines. The Onboard reference system is aimed at developers of vision-enabled industrial automation systems such as robots, inspection equipment and monitoring and surveillance devices. It features a Prophesee-enabled VGA-resolution camera combined with a Qualcomm Snapdragon processor and can be integrated into a production camera system design.

Market forecasters estimate the overall industrial machine vision market to be valued at USD $7.91 billion in 2017 and is expected to reach $12.29 billion by 2023, at a CAGR of 7.61% between 2017 and 2023 (source: Research and Markets). Factors driving this growth include the increasing need for quality inspection and automation, growing demand for AI and IoT integrated machine vision systems, the increasing adoption of Industrial 4.0 technologies, development of new connected technologies, growing demands for predictive maintenance and government initiatives to support smart factories.

The Onboard reference system provides a guide for developers to optimally implement Prophesee's neuromorphic vision technology for a variety of use models, including area monitoring, high-speed counting, vibration measurement, or real-time arc welding monitoring. Based on the company's proprietary technique that uses a bio-inspired approach based on capturing events that change in the field of view of individual pixels (and avoiding the transmission of redundant data), machine vision systems that utilize Prophesee's image data acquisition and processing solutions save computational power, bandwidth, memory and energy.

The event-based approach also enables sensors to achieve much higher dynamic ranges than commonly associated with high-speed vision. And it allows cost-efficient sensors and systems to record events that would otherwise require conventional cameras to run at 10,000 frame/s and more.

"Our technology has been under development for several years and we are excited to demonstrate the first tangible implementation of it that developers can use for their specific product requirements," said Luca Verre, CEO and co-founder of Prophesee. "We are confident that the inherent efficiency of event-based sensing will make it possible for companies to deploy machine vision more widely and no longer have to deal with large amounts of (redundant) data when using cameras at high frame rates to achieve high-speed vision. The combination of performance and efficiency will help speed up production lines, improve quality monitoring, and facilitate better and safer human/machine collaboration in production environments."

The solution is also suited for monitoring and surveillance. The vision sensor's high dynamic range allows operation in difficult lighting environments while producing much less data than a traditional frame-based approach and reducing the computational burden of scene analysis processing.

Prophesee's solution are aimed at improving a range of industrial uses, including accelerating quality assessment on production lines; reducing recalibration for high-speed inspection systems; positioning, sensing and movement guidance for robots to enable better human collaboration; and equipment monitoring (e.g. caused by vibration, kinetic deviations) making the system an asset for predictive maintenance and reduced machine downtime.

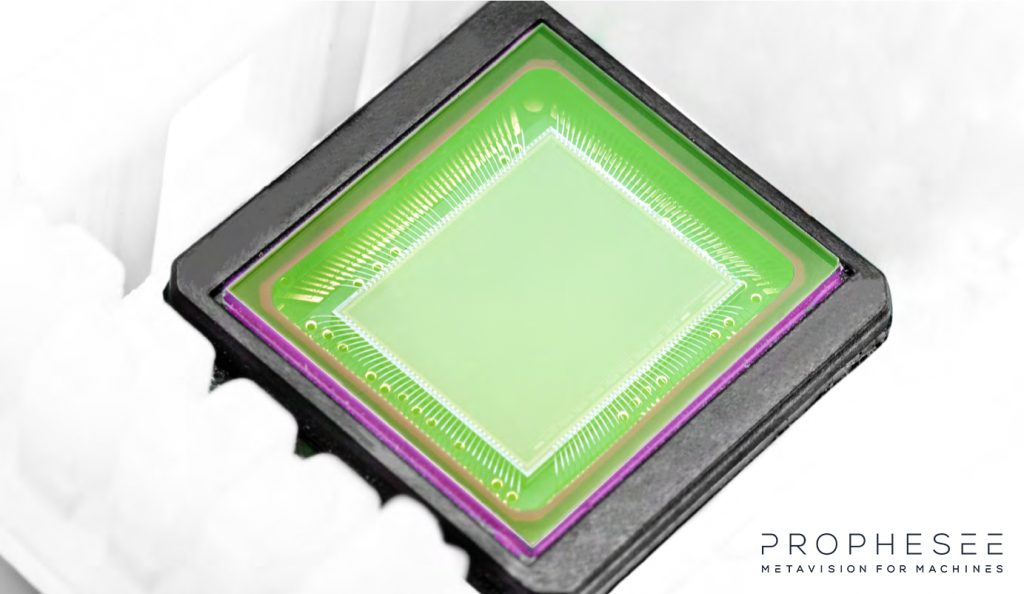

The Onboard reference systems consists of a VGA resolution, 640 x 480 pixel sensor with 15 μm pixels in a 3/4" optical format.

The dynamic range of the Prophesee vision sensor is greater than 120dB, with the ability to operate down to 100 millilux of scene illumination. The sensor is able to capture extremely fast motions thanks to its sub-millisecond temporal resolution.

The Onboard reference system supports comprehensive connectivity options, including Ethernet, USB, HDMI and Wi-Fi.