Walter has introduced the MP6 geometry for turning operations. With the MP6, Walter rounds off its range for medium machining of steel (ISO P). The geometry also has secondary applications in stainless steels, cast iron and super alloys (ISO M, K, S). The MP6 combines features for medium machining, such as a positive rake angle, with those of roughing inserts, for example a strong cutting edge. This makes it the perfect link between the existing MP4 geometry for medium machining (with excellent chip breaking on soft steels) and the RP4 for roughing operations (with tough cutting edge for high feeds) The straight cutting edge of MP6 also makes it an ideal geometry for internal boring operations.

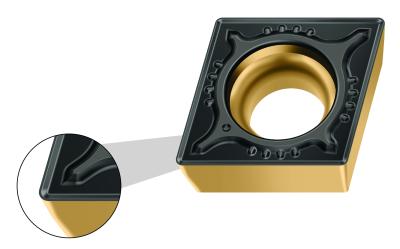

To cover the widest possible range of applications, Walter offers the MP6 geometry in CCMT, DCMT, TCMT and VBMT basic shapes. Its short protective chamfer, which is characteristic of roughing inserts, ensures a high strength of cutting edge, even in challenging conditions, for example when machining forged parts or components with interrupted cuts. The 18° positive rake angle ensures excellent chip control during medium machining.

To prevent vibration, for example with thin-walled components, Walter has given the MP6 geometry an open chip breaker groove. This reduces the cutting pressure even when cutting at a higher depth of cut. This also makes the MP6 ideal for unstable workholding setup and components with long overhangs, for example during internal turning. The new Tiger-tec® Gold grades also have a positive impact on tool life. The WPP10G, WPP20G and WPP30G grades are adapted to different operating conditions, thereby improving tool life and performance across a broad range. Walter specifies feeds from 0.004-0.014 in. and depths of cut from 0.016-0.157 in. as the range for the machining parameters.

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.