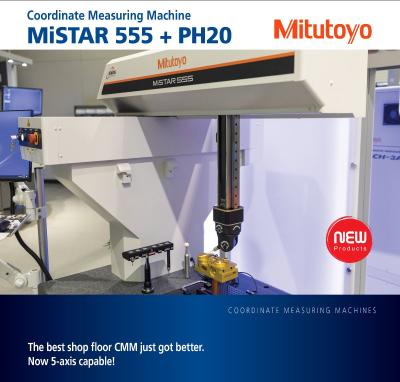

Mitutoyo America Corporation is pleased to announce the release of the MiSTAR 555 CMM with the PH20 5-axis probe system. The best Mitutoyo shop floor CMM just got better with enhanced measuring capability, increased feature access, and a threefold improvement of throughput.

Combined with the MiSTAR’s three-side open architecture, wide accuracy-guaranteed temperature range, environment-resistant absolute scale, and all-in-one space-saving design, the MiSTAR performance is set apart from conventional coordinate measuring machines.

Key features:

- Enhanced measuring capability with probe head touches: Rapid head touches – where the CMM is stationary, the head moves to take a measurement point. The rapid rotary motion of the PH20 head allows measurement points to be taken faster and with improved accuracy, repeatability, and dramatic time savings.

- 5-axis provides increased feature access with infinite probe angles: Infinite positioning guarantees optimal feature access, minimizing stylus changes, thereby improving usability over fixed-angled probe heads. 5-axis motion allows larger part access on the CMM by minimizing space required around the part for probe orientation.

- Dramatic reduction in calibration time: The unique ‘inferred calibration' technique developed for PH20 determines the head orientation and probe position in a single operation, allowing subsequent measurement at any head angle. Further modules only require a few touches on the calibration sphere before use.

- Compatible with the existing range of TP20 modules: Users of the PH20 probe head will immediately have access to the range of proven TP20 probe modules, providing a wide selection of trigger forces, directional sensing options and extensions to meet application requirements. The detachable modules provide crash protection and can be automatically changed using the TCR20 change rack. The TP20 EM2 probe module allows holes greater than 300 mm diameter to be measured without CMM motion.

Contact Details

Related Glossary Terms

- calibration

calibration

Checking measuring instruments and devices against a master set to ensure that, over time, they have remained dimensionally stable and nominally accurate.