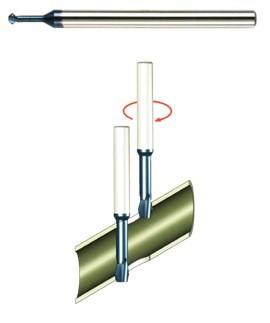

Rugged enough for use with virtually all materials, Carmex’s new Mini Chamfer tools are the ideal solution for

deburring, back chamfering and grooving operations. Designed with spiral flutes for smoother cutting action, the tools offer double-side cutting and are available in both long-reach 45-degree and 150-degree configurations. Constructed from rugged MT8-grade carbide, the surfaces are triple coated with advanced PVD triple coating for high heat resistance, smoother cutting and high performance in virtually all materials.

According to Jim White, national sales manager for Carmex USA, “This latest addition to our family of Mini Tools answers the need frequently expressed by users of Swiss-style lathes for tooling that delivers higher productivity and longer life in operations ranging from conventional materials to the latest special alloys and exotics. The quality and versatility of the new Mini Chamfer tooling continues the Carmex tradition of extreme performance and longer tool life.”

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- chamfering

chamfering

Machining a bevel on a workpiece or tool; improves a tool’s entrance into the cut.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.