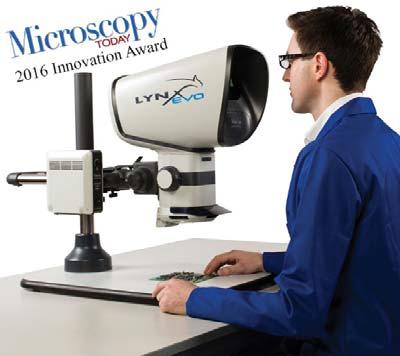

Unlike conventional microscopes, the eyepiece‐less technology built into the Lynx EVO from Vision Engineering overcomes the ergonomic challenges faced with binocular microscopy. Operators experience both optical and

postural ergonomics giving them ease of use with less physical strain. Users can sit back from the viewer giving them freedom of movement which reduces eye fatigue and postural strain associated with a fixed body position required when using a binocular microscope. Another added benefit is that operators do not need to remove glasses or safety glasses to use the Lynx EVO.

Stephen Sanderson, international product manager, Vision Engineering, explains, “by improving user ergonomics, Lynx EVO allows operators to work more efficiently and effectively, maintaining high levels of accuracy for prolonged periods. So the user benefits from significantly improved comfort and the company benefits from improved quality and productivity”.

Lynx EVO employs Vision Engineering’s patented Dynascope eyepiece‐less optical projection technology. At the heart of the Dynascope eyepiece‐less technology is a spinning multi‐lenticular (multi‐lens) disc. On the surface of the disk are more than 3.5 million individual lenses (known as lenticules), which act as independent image‐forming surfaces. Each individual lens has a diameter of just a few microns (0.001mm). The multi‐lenticular disk spins at high speed to merge the millions of individual optical paths into a high‐clarity image.

Light reflects from the Dynascope optics, exiting the single viewing lens as twin (stereo) light paths. The large diameter of these exit rays (approximately 30mm) means users do not need to precisely align their eyes with the viewing lens to see the image, since the exit pupils are projected from the head of a viewing window. This arrangement does away with IPD adjustment, allowing spectacle wearers to keep their spectacles on. In addition, this technology gives the user freedom of head movement. Users can move within the optical path to effectively look around a subject without moving it.

Lynx EVO is used for a range of precision visual inspection and manipulations tasks requiring stereo (3D) imaging, and is especially beneficial for applications requiring prolonged use. Industrial applications include: manufacturing quality inspection of fibre optics, solar cells, packaging, printed circuit boards, engineered components, electro‐mechanical instruments.

Life science applications include: sample investigation (e.g. forensic analysis), sample preparation tasks, critical inspection of medical and laboratory devices and samples (e.g. blades, stents, catheters). Lynx EVO can also be used from behind the glass of a laminar flow cabinet, improving safety, or reducing the risk of contamination to applications such as stem cell research.

Contact Details

Related Glossary Terms

- fatigue

fatigue

Phenomenon leading to fracture under repeated or fluctuating stresses having a maximum value less than the tensile strength of the material. Fatigue fractures are progressive, beginning as minute cracks that grow under the action of the fluctuating stress.