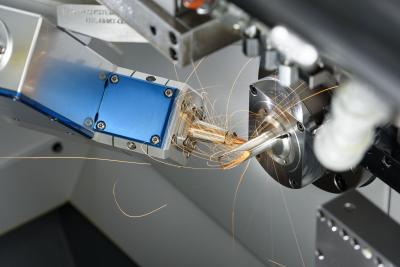

The Marubeni Citizen-Cincom Laser Systems L2000 provides the capability of combining conventional machining and laser cutting on a single machine platform, reducing part handling and ensuring improved part accuracies.

This 10-micron fiber optic system offering high-precision, high-speed laser cutting is completely interfaced to the machine control with the cutting path and offsets fully controlled and edited in the control. As a modular system and not designed for a specific machine, a single system can be purchased and moved to other Citizen's. It can also be retrofitted to some older Cincom models.

The unit can mount on the B-axis tool position for laser cutting at various angles for components that require angular laser cut features. The laser head assembly, which mounts on the gang tool slide of the machine is liquid tight so that it can operate while high-pressure coolant is flooding the workpiece during the machining process. Internal air pressure protects the lens and internal components.

An integrated camera for optical viewing and alignment is included for X-Y beam alignment to the nozzle. The live camera is visible on the included touch monitor, greatly reducing setup time.

Contact Details

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.