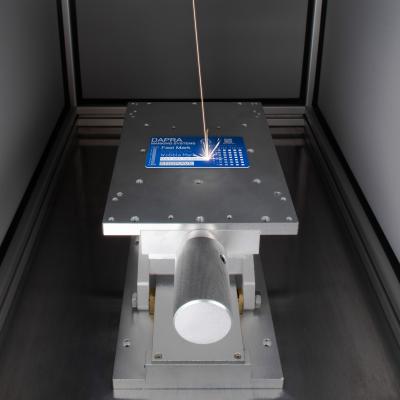

The latest fiber laser part marking solutions from Dapra Marking Systems offer fast cycle times and precise, repeatable, non-contact marking of metals (hardened and stainless steel, anodized aluminum, copper, precious metals), plastics and more. New 200i Series systems feature a compact marking cabinet (18" wide x 20" deep x 17" high) that is ideal for shops that need to mark nameplates and smaller parts for identification and traceability.

Dapra offers a variety of standard cabinet configurations with high-powered laser sources up to 100 Watts for high-speed, high-contrast marking. These systems are ideal for deep engraving both basic text and complex patterns, creating crisp marks in excess of .004” deep with ease. Powerful, intuitive software allows for easy logo import, serialization, date coding, Data Matrix codes, and UID and UDI syntax.

From power and lens options to Class 1 workstation and Class 4 setups, Dapra helps users select the optimal laser system configuration for their specific application material, mark type and budget. Modern fiber lasers are rated for 100,000 hours of life, and these industrial-grade systems are built to last for years to come. Options include:

- Manual and power programmable Z-axis options with up to 12” of standard travel; custom travel lengths available

- Optional rotary D-axis for marking round parts up to 22 pounds (standard)

- Industrial fume extractors

- 2D, UID and 1D barcode readers and verifiers