OnRobot, the maker of tools for collaborative applications, announces the release of its smart, complete-out-of-the-box Screwdriver that allows manufacturers to automate a wide range of assembly processes quickly, easily, and flexibly. This provides welcome relief for manufacturers who are eager to automate repetitive, unergonomic, and often inconsistent manual screwdriving processes, but who struggle to integrate and program typical piecemeal screwdriving systems.

Programming the OnRobot Screwdriver is as easy as entering the appropriate screw length and torque value into the user interface that is integrated into the teach pendant of any leading robot. With precise torque control and embedded axis, the OnRobot Screwdriver automatically calculates the speed and force required for consistent, accurate screwdriving. The Screwdriver can detect incorrect screw length, which can help improve overall quality and reduce scrap. With the Screwdriver’s unique “z-axis,” screws are retracted inside the tool and driven automatically once the robot arm moves into position, which reduces robot arm movement and additional programming. Screws up to 35mm long are retracted completely inside the Screwdriver when moving until the screwdriving process is safely initiated, enhancing its collaborative capabilities.

The Screwdriver can handle a wide range of screw sizes and lengths, from M1.6 to M6, and up to 50mm long. With its simple programming and easily exchangeable bit system, the Screwdriver can be quickly changed over to a different screw size, length or product line in minutes, which minimizes downtime and improves productivity.

“This is one of our most advanced products to date,” says CEO of OnRobot, Enrico Krog Iversen. “We’ve designed an automated screwdriving tool that simplifies a highly complex process for our users, making it cost-effective and easy for manufacturers to see fast results in terms of higher uptime, output, consistency and quality.”

The Screwdriver includes the following robust and intuitive features:

-

Embedded axis for accuracy and easy programming

-

Precise torque control from 0.15Nm to 5Nm

The new OnRobot Screwdriver can be deployed and redeployed for different applications in minutes, with built-in smart features—including precise torque and embedded axis control—that simplify programming and drive productivity, quality, and ROI.

-

Screw sizes from M1.6 to M6, and up to 50mm long

-

Available screw feeders

-

ESD safe for electronics assembly

-

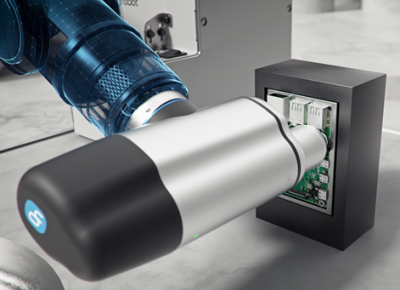

Mounting via OnRobot Quick Changer

The Screwdriver is compatible with OnRobot’s award-winning One System Solution, a platform that provides a unified mechanical and electrical interface between leading robot arms and any OnRobot product. The One System Solution has been newly expanded to include integration with robots from ABB Robotics and Hanwha Precision Machinery. Users of those robots can now also take advantage of the unified mechanical and electrical interface of any OnRobot product, for easier integration and faster ROI.

Contact Details

Related Glossary Terms

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

- robotics

robotics

Discipline involving self-actuating and self-operating devices. Robots frequently imitate human capabilities, including the ability to manipulate physical objects while evaluating and reacting appropriately to various stimuli. See industrial robot; robot.