As with all production line operations, the marking has to be automated for cost and quality control reasons. SIC Marking are specialists in integrated systems which are highly versatile and easy to incorporate into a production environment.

The Parker Hannifin de Vierzon company is a specialist in manufacturing hydraulic pumps, vane and motors. They are dedicated to the rail industry, marine, mobile vehicles (on wheels or on tracks), the military and environment. The site employs 220 people.

"The engraving of the product's plate was carried out by one dedicated operator. It was a very manual task and we wanted to find an automated solution to relocate the operator to another post. When we discussed our marking requirements with SIC Marking, they clearly understood our exact application requirements and proposed the best solution. Because of thedimension of the parts, the gripping of the pieces was a problem. The solution was to put the plates on a tray without all the handling involved," explains M. Marchand of Parker Hannifin.

The plates serve to identify motors and pumps produced on the site. These are blue anodized aluminium plates of 0,5mm of thickness. They contain the following information: the product name, the customer's number, the serial number and the barcode.

"SIC Marking has created a mechanical system of loading plates on the marking machine. The plates are stacked on three chargers in size order. Then, they are lifted by a finger, and positioned for marking. The operation is difficult because the plates are very thin. The presence/absence is controlled. It just needs to re-launch the program and replenish the pieces store," adds Marchand.

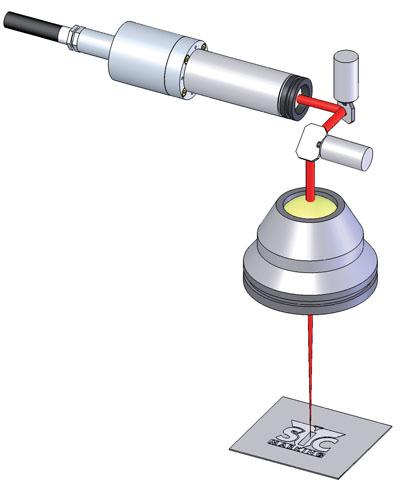

The laser marking machine proposed by SIC Marking is the i103l-g, ideal for the traceability and identification of parts.This equipment is designed to mark at high speed with low operating and maintenance costs. Very robust, the laser machine allows marking on all metallic material (steel, aluminium, stainless steel, titanium) and most plastic parts. The laser source is a Ytterbium YB 20W doped fiber laser.

This solution accommodates the multiple part sizes. The dimension of the plates used by Parker Hannifin are 80x35x0.5mm with 4 fixation holes, 58x35x0.5mm with 4 fixation holes and 76x25x0.5mm with 2 "T" holes. The marking window is 100x100mm, which can cover all the customer needs. The equipment comes with the SICLASER software. It allows the editing and creating of marking folders in Windows. It also allows the integration of the Parker Hannifin database. The variables are transmitted to a controller that manages the marking cycle. Finally, the management in stand-alone, the test Mode (marking tests) and the Diagnosis can be done. The i103l-g laser marking system communicates via RS232 or Ethernet and by E/S TOR (stand-alone card that permits autonomy of the system and to run without PC).

"We have easily learned how to use the accessible software," specifies Marchand. A production cycle lasts 45 seconds and 450 pieces are produced each day. "The system is much faster than what we had before, but this wasn't the crucial point for us. On the other hand, marking precision and flexibility were the other key factors," concluded Marchand.

Contact Details

Related Glossary Terms

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.