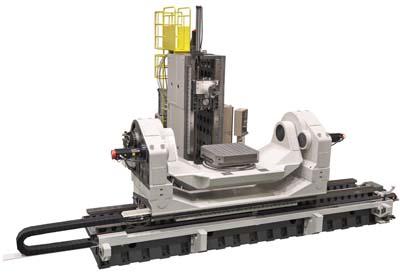

Mitsui Seiki's new 2500mm HU100A-5XLL Horizontal Machining Center is now available and designed for machining large, complex, and heavy (up to 6600 lbs.) hard metal parts.

"We built several custom engineered machines with similar configurations and attributes; it made sense for us to add the HU100XLL to our standard product line," says Mr. Thomas Dolan, Mitsui's Vice President of Marketing and Sales. "The custom engineered machines were supplied to primarily aerospace, power generation, refrigeration, and mold and die parts manufacturers as all of these industries have fundamental common requirements for machine rigidity and stiffness for low frequency machining and high accuracy. We expect demand for this type of rugged, 5-axis equipment to accelerate over the next five years."

The HU100A-5XLL offers an X, Y, Z working envelope of 2500mm x 1750mm x 1400mm (98.4" x 68.9" x 55.1"). The A and B tilting and rotating trunnion table axes represent the 4th and 5th axes of motion. The standard spindle offering is a 50 taper, although many manufacturers taking extra heavy roughing cuts in titanium and tough steels could opt for the HSK 100 or HSK 125 spindle with extra high torque of 3332Nm (2457 lb.-ft.).

The FMS-ready machine has a pallet size of 1700mm x 1000mm (66.9" x 39.4") and accommodates weight up to 3000kg (6600 lbs.). The automatic toolchanger accommodates 360 tools with lengths up to 500mm (19.6"), diameters to 305mm (12"), and weights of 30kg (66 lbs.).

Contact Details

Related Glossary Terms

- automatic toolchanger

automatic toolchanger

Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restores the used tool to the magazine and selects and withdraws the next desired tool from the storage magazine. The changer is controlled by a set of prerecorded/predetermined instructions associated with the part(s) to be produced.

- machining center

machining center

CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger.

- stiffness

stiffness

1. Ability of a material or part to resist elastic deflection. 2. The rate of stress with respect to strain; the greater the stress required to produce a given strain, the stiffer the material is said to be. See dynamic stiffness; static stiffness.

- toolchanger

toolchanger

Carriage or drum attached to a machining center that holds tools until needed; when a tool is needed, the toolchanger inserts the tool into the machine spindle. See automatic toolchanger.