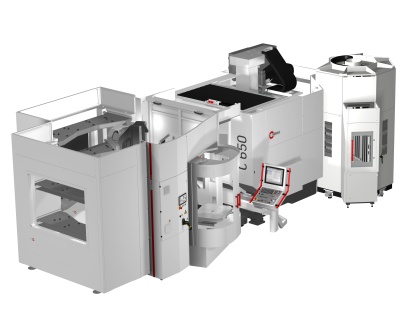

Hermle continues its commitment to automation of its industry leading five-axis machining centers with the introduction of a powerful, compact, and attractively priced automation tool - the HS flex heavy handling system.

The HS flex heavy handling system is designed to be adaptable to five-axis PERFORMANCE-LINE machining centers (C 400 and C 650) as well as the HIGH-PERFORMANCE-LINE models (C 32 and C 42). This also marks the first time that the C 650 is available with automation capabilities.

The HS flex handling system is based on several components, which are supplied and adapted as a complete unit. Only the workpiece storage modules are installed and adjusted on site. As a result, the entire installation – with all Hermle machining centers also being shipped in a pre-assembled state – is available in a very short time, and the user can start machining with little delay.

The flat mineral casting bed, on which the three axes of the handling unit are operated, offer ergonomically very friendly access for the operator. The two double-leaf doors, which have already proven their functional benefits in Hermle’s robot systems, provide a twofold function. During a pallet change procedure, they prevent access by the operator and during machining of the workpiece, they provide access to the working view position and working area while also preventing access to the handling unit.

The rotary, lifting and linear axes of the handling unit enable precise movements of the heavy workpieces up to 1200 kg, including the pallet, between the setup station, storage modules and the machining centers working area. With the ability to crane load machining centers, workpieces with even higher weights and dimensions can be moved into the machine working area. Pallets up to 800 x 630 mm can be handled precisely. To minimize the potential for operator error, the maximum workpiece height is examined beforehand at the setup station, preventing workpieces with dimensions beyond defined sizes from being fed in. The maximum workpiece dimension that can be handled is 800 x 630 x 700 mm (W x D x H).

In the design of this new system, Hermle paid additional attention to the development of the storage modules. One module is installed as standard, and the adaptation of a second module is optionally possible. The modules are structured as a rack, offering maximum customization potential in the pallet/workpiece arrangement. Up to three rack bottoms with a total of up to 9 pallet storage pockets can be ordered per module. If two storage modules are used, a capacity of up to 18 pallet pockets is achievable. Using a specially developed storage generator, which tests both the permitted weights and dimensions (given that a variety of machine models are possible), the storage arrangement can be defined quickly and easily.

The HS flex heavy, the pallet changer and the RS 05-2 robot system are controlled and managed using the proprietary and convenient Hermle Automation Control System, or HACS. HACS allows for smart order management, which intuitively aids the operator in their daily functions via a software solution that can be operated by means of a touch panel. The transparent representation of the orders and required operator actions reduce the organizational downtimes and maximize productivity of the plant. When combined with the Hermle Information Monitoring System (HIMS), which displays machine status in real time and can be shown on any tablet, desktop or smartphone, these two software tools are collectively a cornerstone of Industry 4.0-capable use of Hermle machining centers.

Contact Details

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.