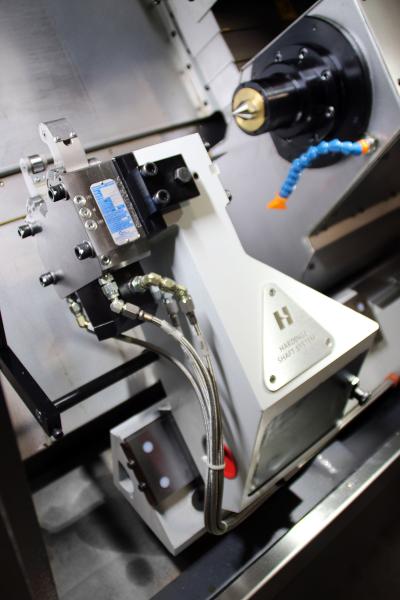

Hardinge announces the introduction of a hydraulically operated steady rest for its Conquest H51 CNC Turning Center. This new attachment is the Forkardt SRFN1 compact steady rest and is the ideal tool to support long workpieces without distorting or deflecting the part.

It features a highly stiff structure, compact design and a fully sealed body for better protection from coolant and chips. The gripping range is 0.24” – 2.76” (6mm – 70mm) and the unit provides 5-micron repeatability.

It also features:

- Hydraulic ports on top and side of cylinder

- Inbuilt safety valve

- Feed-back for maximum opening

- Port for compressed air

- Provision for centralized lubrication suitable for grease or oil

- Front body profile for easy chip flow

- Steady rest unit moves on a dovetail, gripper is programmable.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- steady rest

steady rest

Supports long, thin or flexible work being turned on a lathe. Mounts on the bed’s ways and, unlike a follower rest, remains at the point where mounted. See follower rest.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.