TigerStop offers a new software upgrade for TigerTouch called Dynamic Pack Optimization , which nests packs or bundles of material for the greatest yield. Dynamic Pack Optimization enhances raw material usage and reduces scrap waste.

TigerStop’s Dynamic Pack Optimization optimizes entire packs or bundles of like-profiled material, rather than single pieces. It does so quickly and accurately while tracking material usage statistics data.

“Dynamic Pack Optimization allows operators to achieve maximum productivity. It quickly calculates the greatest number of profiles an operator can load while achieving the best yield and preventing over-cutting of expensive raw stock,” explains Mike Anderson, TigerStop’s saw systems manager.

Dynamic Pack Optimization can be used while processing metal, wood, composites, and plastics in the following industries: furniture, cabinetry, flooring, packaging, pallet manufacturing, fenestration, curtainwall and storefront, automotive, aerospace and mechanical/electrical/plumbing.

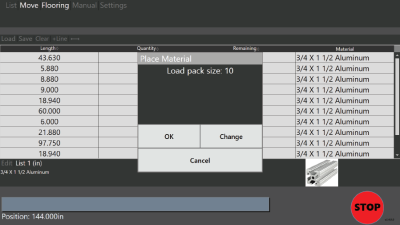

Using TigerStop’s patented TigerTouch tablet software coupled with the Dynamic Pack Optimization software upgrade, the operator simply enters the stock profile he would like to cut or process. The operator then enters the maximum number of like-profiles his saw envelope or machine tool can process at one time. Using its proprietary algorithm, the Dynamic Pack Optimization software tells the operator how many pieces of stock to bundle together in the pack, reportedly resulting in the best yield and productivity, while preventing over-cutting.

Yield and productivity are the ultimate priorities with Dynamic Pack Optimization. Optimizing raw material usage means more of it is turned into end-product and less ends up in the scrap bin.

Contact Details

Related Glossary Terms

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).