If there ever was a process taken for granted and not appreciated it is Keyseating! This fundamental and traditional method to cut keyways in bores has been stagnant and without development for many decades. Yet the quality and sophistication of the components with keyways have greatly improved through smaller tolerances, more exotic materials and greater load carrying abilities. Keyways in high dollar value hubs or gears which have been processed to near completion using CNC turning and possibly grinding operations are often trusted with an antique keyseater for one of the final steps of production. Or worse yet, manually broached by hand in a press using shims to control the final depth!

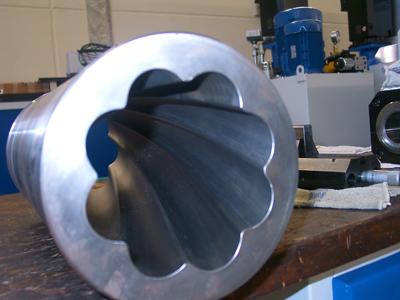

Leistritz, a German machine tool builder, has a line of Keyseaters to match the control and flexibility needed by today's manufacturers to produce a straight and accurate keyway. Their CNC keyseaters are very well suited for cutting small keys yet heavy duty enough for huge keyways, up to 7" wide, as well. The CNC is a valuable time saving device and can optimize the cutting parameters through fully flexible programming of feedrates and cutting speeds, as well as variable depths, if required. The CNC also allows the addition of a rotary table to produce helical grooves for special applications or multiple grooves within a single bore.

Leistritz has also developed keyseaters with linear motors to make full use of modern cutting tool materials, including carbide to cut keyways in already hardened workpieces. The linear motor systems produce the high cutting speeds required to match that needed by the tooling and to shorten the cycle times for a production environment.

With machine strokes up to 60" these machines can cut a wide variety of grooves in steels previously un-thought of with little investment in both tooling and capital.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- cutting tool materials

cutting tool materials

Cutting tool materials include cemented carbides, ceramics, cermets, polycrystalline diamond, polycrystalline cubic boron nitride, some grades of tool steels and high-speed steels. See HSS, high-speed steels; PCBN, polycrystalline cubic boron nitride; PCD, polycrystalline diamond.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- linear motor

linear motor

Functionally the same as a rotary motor in a machine tool, a linear motor can be thought of as a standard permanent-magnet, rotary-style motor slit axially to the center and then peeled back and laid flat. The major advantage of using a linear motor to drive the axis motion is that it eliminates the inefficiency and mechanical variance caused by the ballscrew assembly system used in most CNC machines.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.