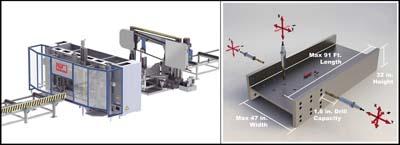

KNUTH Machine Tools USA Inc. has announced new CNC Saw and Drill Press Center technology. The BeamCenter CNC 1200 offers highly productive beam production that is centrally controlled and easily customizable. Users can perform simultaneous 3-axis drilling, marking and sawing for an unbeatable price.

KNUTH CNC Saw and Drill Press Center Features:

Fast and efficient drilling with 3-axis machining and 4 station tool changers per spindle.

Maximum 47" x 31" sawing capacity with a wide swivel range of +60 degree/-45 degree. Feed and discharge unit with material positioning up to 66 feet.

Reliable and accurate marking of static materials with a movable embossing head.

Siemens SIMATIC Control: The BeamCenter CNC 1200 is equipped with the user-friendly Siemens SIMATIC PC control. Programs for automatic operation of the BeamCenter can be captured, edited and managed directly at the machine. Its easy to use input templates (masks) provide direct access to all machine and machining data.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- drilling machine ( drill press)

drilling machine ( drill press)

Machine designed to rotate end-cutting tools. Can also be used for reaming, tapping, countersinking, counterboring, spotfacing and boring.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- sawing

sawing

Machining operation in which a powered machine, usually equipped with a blade having milled or ground teeth, is used to part material (cutoff) or give it a new shape (contour bandsawing, band machining). Four basic types of sawing operations are: hacksawing (power or manual operation in which the blade moves back and forth through the work, cutting on one of the strokes); cold or circular sawing (a rotating, circular, toothed blade parts the material much as a workshop table saw or radial-arm saw cuts wood); bandsawing (a flexible, toothed blade rides on wheels under tension and is guided through the work); and abrasive sawing (abrasive points attached to a fiber or metal backing part stock, could be considered a grinding operation).

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).